In the early years of the horizontal unconventional gas boom, I was working for a big independent E&P oil & gas company, and we did some microseismic analysis with MicroSeismic, Inc. At the time, this consisted of drilling a vertical well near the path of the future horizontal well. After the horizontal well was drilled, cased, cemented, and perforated, geophones would be lowered down the vertical well to essentially “listen” while the horizontal well was hydraulically fractured. I thought of it as “mapping the frac.” The data would be formulated into a time-simulation of where the frac went, both out into the formation and above and below it. We could use it to estimate where the frac barriers (harder formations that create a boundary) were and how effective they were. The time-simulations, or frac movies, were fun to watch. A few years later, I went to a talk about microseismic at one of the local geological society meetings. The use of microseismic had become more common then and was used more for field and pad studies when multiwell fracturing methods like zipper fracturing were beginning to be deployed. Microseismic is one of the best tools for evaluating and understanding hydraulic fracturing dynamics. It is a form of passive seismic, which is seismic that listens to acoustic signal events with geophones, rather than providing a vibration source such as dynamite or vibro-seis trucks, which are used in reflection seismic surveys. Below is a technology timeline for microseismic development.

Microseismic for Oil & Gas

According to MicroSeismic,

Inc.’s website, microseismic can inform decisions about hydraulic fracturing

optimization, stage spacing optimization, well spacing optimization, and fault

avoidance. It can also be used for assessing refracs and parent-child well

interactions. Hydraulic fracture monitoring can provide essential information

about how a particular rock formation breaks and where the energy of the frac

goes. If there are natural fractures or faults, referred to as geohazards, that

could steal the frac energy and result in an ineffective frac job overall, they

will likely be seen on the time-simulations, which are really time-movies of

the detection events. Microseismic has been absolutely essential in hydraulic

fracture modeling, monitoring, and understanding.

MicroSeismic, Inc. lists 68

technical papers on its website authored by its employees, stretching back to

2006. There are 106 articles available going back to 2005. These are all

available for free. More recent papers include stress shadow modeling,

multifrac monitoring, and CO2 plume monitoring. There are also abundant videos,

podcasts, and blog posts.

Microseismic for Geothermal

Passive seismic has long been

used in geothermal exploration and development, due to those regions where

geothermal is developed being seismically active. Finding sources of seismicity

can lead to the discovery of hot spots ideal for geothermal development.

Microseismic is used to listen for natural seismicity in geothermal

exploration, but can also be used in enhanced geothermal systems (EGS)

projects, which utilize hydraulic fracturing just as is done in the oil &

gas industry. One such project recently announced is Mazama Energy’s Super Hot

Rock (SHR) Demonstration Project in Central Oregon near the Newberry Volcano.

“Newberry Volcano is a shield stratovolcano in the

Cascade Volcanic Arc, located south of Bend, Oregon, USA, and 35 miles east of

the Cascade Range. It contains one of the largest geothermal heat reservoirs in

the western United States and has been extensively studied for the last 50

years. In 2008, two hot, 3,000-meter-deep boreholes were drilled in the

geothermal lease area on the western flank of the volcano which reached

temperatures exceeding 320°C; however, no natural hydrothermal system was

evidenced.”

The location with the very hot, dry rock at relatively shallow depth is more suited to EGS, which requires hydraulic fracturing to create a hydrothermal system. MicroSeismic, Inc.’s MicroThermal Energy will collaborate with Mazama Energy and the DOE on the project. They are expected to map the connectivity of the induced fracture network between the two wells. This should be an interesting and important project that may help establish ESG in super-hot rocks. Mazama Energy's depiction of the project is shown below.

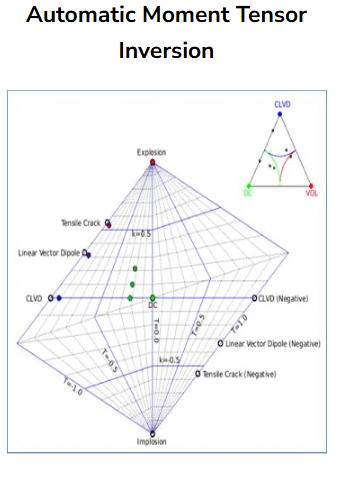

Jon McKenna, Ph.D., of

MicroSeismic, Inc., recently presented at AAPG’s geothermal workshop. He noted

that the company’s 3D fracture propagation analysis can be compared to

automatic moment tensor inversion (AutoMTI) to verify fracture attributes. As

in oil & gas, stress shadows can be seen, and a stimulated reservoir volume

(SRV) can be calculated. The interaction between injection and producing wells

can be determined by microseismic. Both wells need to be permeable, and the

injection well often has to be repressurized.

Microseismic for CO2 Sequestration Plume Monitoring

MicroSeismic, Inc. touts its

CCS services as follows:

“Real-Time CCUS Monitoring Solutions for Class VI Wells

for Measurement, Monitoring, Verification (MMV) – Before, During, and Post

Injection.”

On April 30, they reported that they deployed their “advanced

subsurface imaging and monitoring technology, branded as CO2SeQure®” at an

active CCS site, noting that stored carbon must also be secured carbon, which

is the function of measuring, monitoring, and verification (MMV).

Microseismic for Sinkhole Detection

MicroSeismic, Inc.’s sinkhole

detection solution is called Karst Alert. The challenges and benefits of

sinkhole/karst detection are shown below. I wonder if the Karts Alert

technology can also help with mine subsidence.

Microseismic for Pipeline Leak Detection

MicroSeismic, Inc. uses its

advanced fiber optic, distributed acoustic sensing (DAS) leak detection

technology to detect leaks in water and CO2 pipelines. The benefits are shown

below, according to the website.

References:

MicroSeismic

Deploys DOE Funded Carbon Sequestration Monitoring System. MicroSeismic, Inc.

Press Release. April 30, 2025. Microseismic

- MicroSeismic Deploys DOE Funded Carbon Sequestration Monitoring System

Mazama

Energy & MicroThermal Energy Embark to Drill Deeper with Enhanced

Geothermal System (EGS). MicroSeismic, Inc. Press Release. May 19, 2025. Microseismic

- Mazama Energy & MicroThermal Energy Embark to Drill Deeper with Enhanced

Geothermal System (EGS)

Karst

Alert, Sinkhole Detectrion. MicroSeismic, Inc. Microseismic

- Mazama Energy & MicroThermal Energy Embark to Drill Deeper with Enhanced

Geothermal System (EGS)

Advanced

Fiber Optic, Distributed Acoustic Sensing (DAS) Leak Detection Technology. MicroSeismic,

Inc. Microseismic -

Monitoring for Water Leaks

Newberry

Project. Mazama Energy. Newberry -

Mazama Energy

No comments:

Post a Comment