When I was a mud logger many years ago, we would often do gas ratio

analysis to estimate hydrocarbon types based on thermal maturity. There are

certain rules of ratios that can indicate what the hydrocarbon type(s) will be

when the well is produced. It was a simple plotting exercise of calculating

ratios of alkanes/NGLs, such as ethane and propane, through a hydrocarbon show

during drilling and comparing them to a chart. The information could be used to

predict whether hydrocarbons would be productive and, if so, what hydrocarbon

type(s) would be produced. Gas ratio analysis is considered to be a geochemical

technique. Basically, all that is needed for gas ratio analysis is a gas

detection and measurement system and a gas chromatograph that gives levels of

light alkanes from methane (C1) to pentane (C5). This is a standard mud logging

unit setup. A gas detection system utilizes a gas trap with an agitator to

collect gas from the drilling mud and pumps it into a detector, which measures

the magnitude of gas shows. The chromatograph breaks the gas down into

percentage components of the total gas. While such analyses are not generally

needed in development drilling, they can be important for exploratory drilling

or wildcat wells. Such analysis can also help with optimizing the choice of

perforation zones. A typical setup is shown below. I remember when I first used

the new quantitative gas measurement (QGM) agitator that was developed by

Texaco. It was powered by electricity and was deemed shockproof. I also

remember walking past it one time, getting shocked by it without even touching

it! When examining gas from a mud log one must compensate for background gas –

the steady gas already coming into the mud system before the gas shows being

evaluated, and gas from individual events in drilling such as when making a

connection (connection gas) and following a trip out and back in the wellbore

(trip gas).

B.O. Pixler wrote about gas ratio analysis

in a 1969 article in the Journal of Petroleum Technology. In describing the

methodology, he noted the basis for gas detection analysis:

“Ordinarily, when formation cuttings are drilled they retain much of

the formation pore fluid. This fluid is released to the mud column as the

cuttings travel up the annulus. Most of the formation fluid in the cuttings

will be "produced" into the drilling mud during the top 500 ft of

hole travel. Conventionally, a mud sample is diverted to a mechanically

operated gas trap to obtain a sample of the gas in the mud. The efficiency of

this trap is from 15 to 70 percent, depending upon the gel strength of the mud,

the amount of mud flowing through the trap and the rotation speed of the trap

impeller.”

Some very good papers and analyses

illustrating the value of gas ratio analysis have come out in the past decade

or so. A case study from a fractured carbonate reservoir in a Kuwait oil field

from a 2012 AAPG conference covers fluid detection and gas analysis. The paper

noted that gas detection during drilling and further analysis was “particularly

significant in exploration of high pressure, tight, fractured carbonate

reservoirs in Kuwait, which are drilled with Oil Base Mud (OBM) having high

barite content causing severe formation damage.” The data is important for

formation evaluation, identification of productive intervals, fluid

characterization, and identification of gas/oil and oil/water contacts. Factors

that may affect gas readings include the diameter of the hole, the size of the

chamber holding the agitator, mud properties and mud additives, the distance

between the gas trap and the wellbore, and the nature of the reservoir. Another

paper describes even more factors: “volume of gas per unit volume of

formation; degree of formation flushing; rate of penetration; mud density and

mud viscosity; formation pressure; gas trap efficiency; gas detector

efficiency; variability of mud flow rate.” Thus, we can see that comparing

ratio analyses from different wells would give the best data if those

parameters were similar, and that interpretation of the data is

qualitative rather than quantitative.

The first gas ratio analysis is known as

the gas quality ratio and simply divides total gas (TG) by all the other

alkanes (C2-C5) combined.

Gas Quality Ratio = GQR = TG / (C1 + 2*C2 + 3*C3 + 4*(iC4 + nC4) + 5*(iC5

+ nC5))

The gas quality ratio is used to determine the quality of the gas data

and eliminate data that is the result of contamination in the mud system and

gas from non-productive zones. The plot below shows C1 versus C1/C2 + C3 + C4 +

C5 and applies a cutoff to eliminate gas from contamination.

Other gas ratio analysis equations are shown below:

Gas dryness = C1/C1+C2+C3+C4+C5

Pixler ratios (C1/C2, C1/C3 and C1/C4)

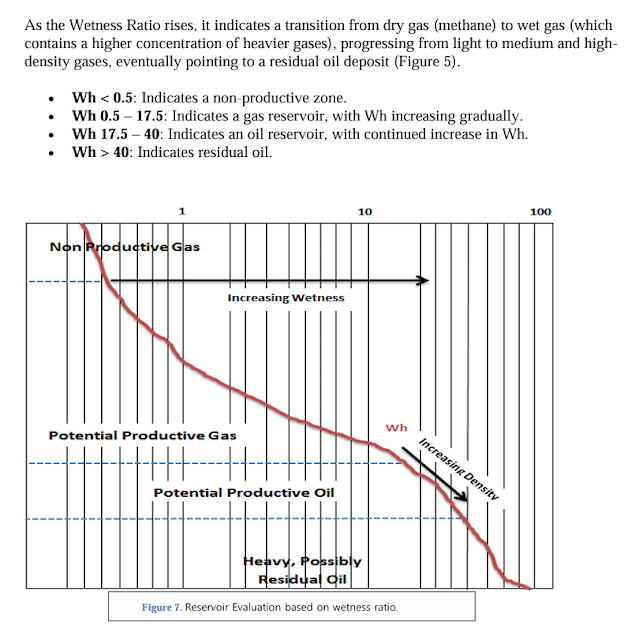

Wetness (Wh) = 100 * (C2 + C3 + C4 + C5) / (C1 + C2 + C3 + C4 + C5)

Balance (Bh) = (C1 + C2) / (C3 + C4 + C5)

Character (Ch) = (C4 + C5) / C3

These are used to determine fluid type, contacts, and evolution. The

authors explain as follows:

“The first equation, gas dryness C1/Sum is a good indication for the

wetness of the gas, the fluid evolution, and the discontinuities in the fluid.

The second method, Pixler ratios, the magnitude of the methane to ethane ratio

determines if the reservoir contains oil, gas or water or if its nonproductive

water zone (Pixler 1969). Also from Pixler ratio slope line used to indicate

permeability of reservoir as steep slope indicate tight zone. The third method

is the relation between wetness and balance that allows us to determine quality

and productivity of hydrocarbon contained in drilling fluid. Regarding to

character ratio, the presence of a dense hydrocarbon fluid can be confirmed and

this should aid in the distinction of a very wet gas from very high gravity oil.”

The graphs and tables below are from a 2015 study of gas ratio analysis in the Hovsan Oil Field in Azerbaijan from a paper in the Journal of Geological Resource and Engineering. The first one is a blank graph similar to the ones we used to use for plotting.

A newer paper from 2024 in the Global Scientific Journal explores gas ratio analysis in a field in Oman. Graphs and figures from the paper are shown below. The first one shows a typical gas trap setup and a typical mud log/gas chromatograph plot.

Geochemist Sheng Wu has done some

interesting work comparing gas ratio analyses for shale gas and oil in

different reservoirs. He notes the difference of the Vaca Muerta shale from

other type I marine basins:

“Vaca Muerta fits a type I as many US marine type I, but the GOR and

API differ significantly for the same vRo.”

He notes that the wetness ratio of the Vaca Muerta remains constant,

which does not conform to the normal wetness-maturity pattern. He thinks this

is due to the hypersaline nature of the reservoir fluids and a “PVT process

that altered the dissolved gas in the shale oils.”

“The value of using isotope is not just to get maturity, but also to

compare with wetness, API and GOR data to find out the correct source rock type

and then use the correct template for maturity, wetness, API and GOR

correlation.”

Wu also did some work in the Marcellus wet

gas window, determining that PVT separation occurred in those areas as

evidenced by abnormal gas ratios, particularly the gas wetness ratio exceeding

50%.

“If operators could further optimize the landing and drilling of the

lateral targeting the exact PVT separated liquid part and gas part separately,

we could have improved recovery for both liquid and gas as well as have a

better prediction of the NGL production.”

He notes a paper by Dr. Walker about abnormal behavior in wet gas

production in the Eagle Ford that was explained as adsorbed methane release,

but that he thinks is due instead to PVT separation. I do know that the

Marcellus formation has a high degree of adsorbed gas compared to many other

formations, including shales. However, he thinks that the abnormally high gas

wetness in both formations is the result of

“PVT induced oil ring producing simultaneously with some gas tops for

starting GOR at 3MCF/bbl.”

Finally, he notes that gas isotope logging in real-time or near

real-time is available as an added mud logging service and can help delineate

wet gas producibility by precise zone targeting.

“Here we showed that isotope-maturity-wetness-GOR/CGR-PVT relationship

could subtly & substantially change the production and isotope logging

coupled with other geochemical logging and modeling tools could give

unprecedented maturity resolution and also to each foot in the drilling,

vertical or lateral. Plus, well-site isotope mud logging is available now to

delineate every foot of the lateral or vertical at a fractional cost of

laboratory based isotope analysis now.”

Wu's work shows the value of gas ratio analysis in deeper geochemical analysis, which I admit, is difficult to comprehend fully without a strong background in hydrocarbon geochemistry.

References:

East

Ohio PVC monomer derailment, wet shale gas production in Appalachian, Eagle

Ford, Permian and relation to isotope applications. Sheng Wu. March 23, 2023.

LinkedIn. (18) East Ohio PVC monomer

derailment, wet shale gas production in Appalachian, Eagle Ford, Permian and

relation to isotope applications | LinkedIn

The

isotope-maturity-wetness of shale oil & gas. Sheng Wu. July 22, 2023.

LinkedIn. (18) The isotope-maturity-wetness of

shale oil & gas | LinkedIn

Application

of Gas Ratio Analysis in Reservoir Evaluation – Case Study in Burhan Land

Field, Burhann, Oman. Ahmed Meneassy. Zubair Oil and Gas, Muscat, Oman. Global

Scientific Journals. Volume 12, Issue 8, August 2024, Online: ISSN 2320-9186. *Application_of_Gas_Ratio_Analysis_in_Reservoir_Evaluation_Case_Study_in_Burhan_Land_Field_BURHANN_OMAN.pdf

Gas

Ratio Analysis in Hovsan Oil Field. Samir Hashimov. Journal of Geological

Resource and Engineering 1 (2015) 42-48 doi:10.17265/2328-2193/2015.01.006. Microsoft Word - 6-JGRE20141102-1

Fluid

Detection in Carbonate Reservoirs utilizing Gas Analysis-A Case Study. Ali Abu

Ghneej, Jalal Dashti, Badruzzaman Khan, Heyam Ammar, Abdulrazaq AL-Nabhan,

Sunil K. Singh, Talal Al-Adwani, and Nacif Marai. AAPG Search and Discovery

Article #41116. February 28, 2013. *Adapted from extended abstract prepared in

conjunction with poster presentation at AAPG International Convention and

Exhibition, Singapore, 16-19 September 2012. Fluid Detection in Carbonate

Reservoirs utilizing Gas Analysis-A Case Study; #41116 (2013)

Formation

Evaluation by Analysis of Hydrocarbon Ratios. B.O. Pixler. Journal of Petroleum

Technology. 21 (06): 665–670. Paper Number: SPE-2254-PA. June 1, 1969. Formation

Evaluation by Analysis of Hydrocarbon Ratios | Journal of Petroleum Technology

| OnePetro

No comments:

Post a Comment