Reusing waste materials is a key component of developing successful circular economies, and one that is working well is the reuse of steel slag. Slag from blast furnaces has been used in construction since the 1800s. Slag has been used since then in road construction, for railroad ballast, and as aggregate in concrete. Slag can be of different types with different compositions, depending on the process that produced it. Wikipedia gives a general definition of slag as a:

“…by-product or co-product of smelting (pyrometallurgical)

ores and recycled metals depending on the type of material being produced. Slag

is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be

classified as ferrous (co-products of processing iron and steel), ferroalloy (a

by-product of ferroalloy production) or non-ferrous/base metals (by-products of

recovering non-ferrous materials like copper, nickel, zinc and phosphorus).”

Steel slag has been used for

decades in Japan for road construction. It can sequester carbon through the

chemical process of carbonation if exposed to an oxygenated environment. It has

been proposed for use in green buildings, coastal protection, and agriculture. It

is made of calcium, magnesium, and silicon compounds. In the

past, it was discarded in landfills.

There are some potential

environmental impacts, including leaching of toxic heavy metals, such as

vanadium and chromium, which are often trace elements in the slag. A 2007 study

in the Journal of Hazardous Materials showed that the amounts of chromium and

vanadium that leach out over time depend on the chemical forms of these

materials in the slag. The study showed that the form of chromium (Cr) in Basic

Oxygen Furnace (BOF) steel slag is less mobile and in a less toxic form, but

vanadium is mobile and readily leached out in a toxic form.

“X-ray absorption near-edge

structure (XANES) spectroscopy indicates that Cr is present in the less mobile

and less toxic trivalent form and that its speciation does not evolve during

leaching. On the contrary, V which is predominantly present in the 4+ oxidation

state seems to become oxidized to the pentavalent form (the most toxic form)

during leaching.”

Non-ferrous slags tend to have higher concentrations of

toxic heavy metals.

Construction and Concrete

Slag has long been used in

road construction “(e.g. asphaltic or unbound layer) due to its very

high stability and superior skid and wear resistance.” Granulated

blast-furnace slag is ground into a powder for use in concrete. According to

Wikipedia:

“Ground granulated blast-furnace slag (GGBS or GGBFS) is

obtained by quenching molten iron slag (a by-product of iron and steel-making)

from a blast furnace in water or steam, to produce a glassy, granular product

that is then dried and ground into a fine powder. Ground granulated blast

furnace slag is a latent hydraulic binder forming calcium silicate hydrates

(C-S-H) after contact with water. It is a strength-enhancing compound improving

the durability of concrete. It is a component of metallurgic cement (CEM III in

the European norm EN 197). Its main advantage is its slow release of hydration

heat, allowing limitation of the temperature increase in massive concrete

components and structures during cement setting and concrete curing, or to cast

concrete during hot summer.”

The ground granulated blast-furnace slag (GGBS) is used to

make slag cement, which improves the durability of the concrete. GGBS cement

sets more slowly than concrete made with Portland cement, but it gains strength

over time and offers other advantages, including improved resistance to

alkali–silica reaction (ASR), which can damage concrete.

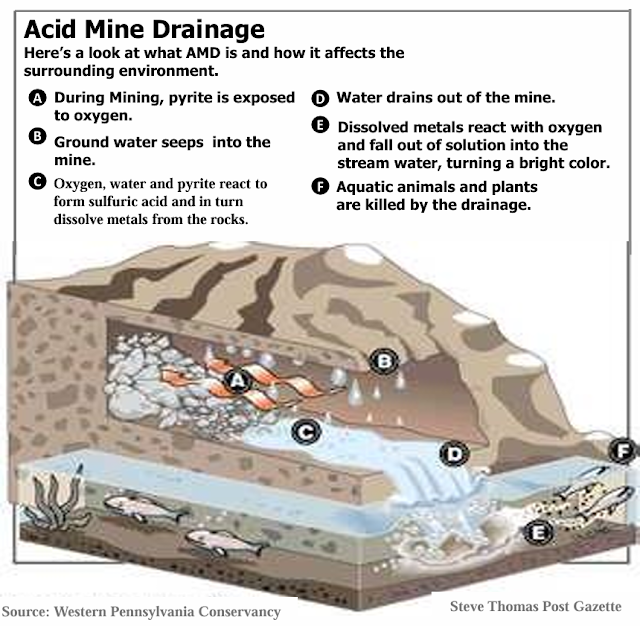

Acid Mine Drainage Treatment and Wastewater Treatment

A 2014 paper in Chemical

Engineering Journal monitored the performance of steel slag leach beds in acid

mine drainage treatment in Southeastern Ohio. Steel slag leach bed treatment is

common here in my region. Steel slag produces alkalinity, which can neutralize

acidic acid mine drainage and precipitate metals.

“Steel slag leach beds (SLBs) are a newer and

potentially promising treatment method for AMD-affected waterways. Steel slag,

a waste product from steel manufacturing, contains high concentrations of

readily dissolvable alkalinity on its surface. The alkalinity is present

primarily as Ca(OH)2 and Ca-(Fe)-silicates.”

The biggest problem with SLBs is that calcium carbonate

precipitates on the slag surfaces, effectively blocking or clogging the

treatment process. Piping can be affected as well. Thus, the slag needs to be

replaced fairly often as the ability to neutralize the acidic waters is

degraded.

One of the major advantages

of SLBs is the low cost of slag, $10-15 per ton, compared to lime (CaO) and

limestone (CaCl), which are $35 per ton, according to a 2021 presentation by

the National Slag Association. SLBs produce less sludge than lime and limestone

leach beds, which means sludge disposal costs are lower.

Agriculture

Slag, as magnesium and

calcium silicates, has the ability to provide alkalinity to acid soils, raising

the pH of the soil. Other benefits of steel slag include neutralization of Al3+

toxicity in acid soils and increased nutrient content, such as phosphorus,

calcium, magnesium, some micronutrients, and silicon. Silicon fertilization is

discussed below from the journal Recovery and Utilization of Metallurgical

Solid Waste:

“Slag application favors the increase of pH and the

availability of nutrients such as Ca, Mg, and Si in the soil, which leads to

the increase in the absorption of these elements by the plant, favoring the

growth and yield of the crops. Slags application may supply silicon which is

considered a beneficial element to plants. Silicon may bring benefits to plants

such as reduction of foliar diseases; improvement in pest control;

increase in photosynthetic capacity due to the silicon benefit to the

architectural activity of the plant, leaving the leaves more upright; and

improvement in the use of water by the plant. Si may also influence the uptake

and translocation of various macro- and micronutrients and increase plant

tolerance to excess of Mn and Fe and Zn, Al, and Cd.”’

Carbon Sequestration

Among industrial wastes,

slags have the highest potential for carbonation, the chemical uptake of

atmospheric CO2. A March 2024 paper in the Journal of CO2 Utilization explores

steel slag carbonation for carbon sequestration potential. The process of

carbonation in the steel and concrete industries has significant carbon

sequestration potential. The abstract and some figures from the paper are given

below.

The paper’s conclusion notes

the complexity of carbonation reactions and rates of reaction influenced by

factors such as temperature and pressure. They also note that carbonation has

great potential in these industries:

“The carbonation of steel slag holds great promise for

achieving carbon neutrality ambitions, not only in the steel industry, but also

in the cement and concrete industry which is another hard-to-abate sector. As

such, the value-added use of carbonated steel slag can contribute to fostering

waste-to-resource economy and enabling faster attainment of sustainable

development goals. Continued research and collaboration among scientists,

engineers, and policymakers are crucial for advancing this field and realizing

its full potential. By harnessing the massive potential for carbonation, we can

transform steel slag from a waste product into a valuable resource,

contributing to a greener future and a more sustainable steel sector.”

A January 2025 paper in

Fundamental Research explores different methods of steel slag-based carbon

sequestration, including direct carbonation, direct gas-solid carbonation,

direct aqueous carbonation, indirect acidic solution, and indirect aluminum

salt solution. Several of these processes are being explored in the lab phase,

but could be tested as pilot demonstrations at some point. The paper’s

conclusion is given below, followed by a table of the CO2 sequestration potential of electric arc furnace (EAF) slag and basic oxygen furnace (BOF) slag.

“In this study, the research and development on CO2

sequestration using steel slag (SS) was summarized. The SS-based carbon capture

and storage (SS-CCU) process is divided into direct and indirect carbonation.

The direct SS-based carbonation process is considered as an economical method

because of the involvement of cost-effective raw materials and simple

equipment. However, the product layer during the carbonation process greatly

limits the further enhancement of conversion degree of Ca. For the indirect carbon

capture process, the Slag2PCC process is a promising approach to achieve the

dual goals of CO2 sequestration and value addition of SS. Future studies on

improvement of the process may aid in increasing the selective extraction of

calcium and promoting the commercial application of carbonated products. SS is

a mixture of numerous types of minerals; therefore, some Ca and Mg enriched in

refractory minerals affect the carbonation efficiency. Thus, the SS carbonation

efficiency may be improved by enriching Ca and Mg into the high-reactive phase

through controlling the crystallization process of the molten slag. Finally,

the treatment of end products and solid residues generated by the SS-CCU

process and environmental footprint, and risk assessments undeniably need

further systematic explorations for which life cycle assessment is a suitable

quantitative and standardized tool.”

References:

The

Steel Slag Secret: How a Waste Material Is Reinforcing Roads and Fighting

Climate Change. Maria Faith Saligumba. Discover Wild Science. April 2025. The Steel Slag Secret: How a Waste

Material Is Reinforcing Roads and Fighting Climate Change

Performance

of steel slag leach beds in acid mine drainage treatment. Elaine R. Goetz and R.

Guy Riefle. Chemical Engineering Journal. Volume 240, 15 March 2014, Pages

579-588. Performance of steel slag leach beds

in acid mine drainage treatment - ScienceDirect

Environmental

impacts of steel slag reused in road construction: A crystallographic and

molecular (XANES) approach. Perrine Chaurand, Jerome Rose, Valérie Briois, Luca

Olivi, Jean-Louis Hazemann, Olivier Proux, Jérémie Domas, and Jean-Yves Bottero.

Journal of Hazardous Materials. Volume 139, Issue 3, 31 January 2007, Pages

537-542. Environmental impacts of steel slag

reused in road construction: A crystallographic and molecular (XANES) approach

- ScienceDirect

Utilization

of Steel Slag to Remediate Acid Mine Drainage. National Slag Association.

August 2021. UTILIZATION OF STEEL SLAG TO

REMEDIATE ACID MINE DRAINAGE

Research

progress of steel slag-based carbon sequestration. Qing Zhao, Chengjun Liu, Xiaohui

Mei, Henrik Saxén, and Ron Zevenhoven. Fundamental Research. Volume 5, Issue 1,

January 2025, Pages 282-287. Research

progress of steel slag-based carbon sequestration - ScienceDirect

Carbon

dioxide sequestration through steel slag carbonation: Review of mechanisms,

process parameters, and cleaner upcycling pathways. Christopher DiGiovanni,

Ousmane A. Hisseine, and Adedapo Noah Awolayo. Journal of CO2 Utilization. Volume

81, March 2024, 102736. Carbon

dioxide sequestration through steel slag carbonation: Review of mechanisms,

process parameters, and cleaner upcycling pathways - ScienceDirect

Slag.

Wikipedia. Slag - Wikipedia

Ground

granulated blast-furnace slag. Wikipedia. Ground

granulated blast-furnace slag - Wikipedia

The

Comprehensive Utilization of Steel Slag in Agricultural Soils. Angélica

Cristina Fernandes Deus, Rosemary Marques de Almeida Bertani, Guilherme

Constantino Meirelles, Anelisa de Aquino Vidal Lacerda Soares, Lais Lorena

Queiroz Moreira, Leonardo Theodoro Büll and Dirceu Maximino Fernandes. Recovery

and Utilization of Metallurgical Solid Waste. Edited by Yingyi Zhang. December 31,

2018. The Comprehensive

Utilization of Steel Slag in Agricultural Soils | IntechOpen

No comments:

Post a Comment