In recent years

the impressive lengths of horizontal well lateral sections, approaching 30,000

ft in some cases, have been emphasized. However, there are other emerging horizontal

and multilateral well designs that are being used to better access reserves and

better optimize their production.

It is not

uncommon for directional drillers to have to steer around certain areas, often

due to unleased acreage. I have worked on several wells that have turned the

azimuth several degrees to avoid crossing areas where access is forbidden. I have

also worked on many wells where the curve was drilled behind or to the side to

maximize lateral footage.

Multilateral

wells have a single main wellbore and usually several shorter wellbores

branching off. Other designs may include two main wellbores. These wells as

well as multiple wells on a single pad require what is known as anti-collision

analysis. This involves planning for each leg trajectory and not deviating too

much from each trajectory.

The U-shaped

lateral has emerged as a preferred way to optimize acreage access and

production. These are becoming more popular every year in applicable situations.

Canada’s thermal

oil plays require optimized reservoir access for different reasons. Some of

these wells are stimulated with steam to produce the oil and these designs are

how reservoir access is optimized.

The U-Lateral/U-Turn/Paperclip/Horseshoe Pattern

The U-lateral is

a preferred design for its simplicity and order. The goal is really to have two

parallel well bores to take advantage of the optimum regional stresses. These

laterals can be drilled with existing technology and as World Oil reports there

are now about 70 of these wells drilled. They can allow an operator to better

optimize their use of acreage. As noted, since the first U-lateral was drilled

by Shell in 2019, there are now about 70, with 27 drilled in 2023 and more than

that drilled so far in 2024.

Shell's 2019 U-Lateral. Source: Journal of Petroleum Technology

The Delaware

Basin is the most active area for U-laterals with 30 wells but as shown below

they have been drilled in several U.S. basins. The Denver-Julesburg (JD) basin

is second with 14 wells. Occidental and PDC lead in U-laterals with ten each. Chevron

bought PDC and thus far has drilled five more U-laterals. Matador has noted cost savings on their U-lateral projects. The cost savings comes mainly from doubling the

amount of horizontal that can be drilled with a single vertical section of the

well. Two-mile lateral is more

economical than a one-mile lateral. Shell noted cost savings on their first U-lateral:

“From an economic perspective, the horseshoe well saved

25% on rig time and about 20% on total cost compared with drilling two wells of

the same lateral lengths. To a lesser degree, some savings was achieved on the

completions side by requiring only one coiled-tubing run instead of two.”

Hole sizes for U-laterals have varied between 6” and 8-3/4”. The turn has not been a problem with modern rotary steerable system (RSS) drilling motors as long as dogleg severity (DLS) stays as projected. Some wells can be drilled to total measured depth without tripping out. World Oil is the source of the following two graphics

Locations of U-Laterals. Source: World Oil

In the case of

Shell’s early U-lateral, the wellbores were left 1300 ft apart leaving room

between them for another well. I wonder how often that is applicable and what the shortest distance achievable of the parallel wellbores of a single U-lateral is. It appears that a well in between the U would be required in most cases since that can really optimize spacing. I would think that a 10-12 degree turn per a hundred feet means that

turning 180 degrees could take as much as 1800 feet with much of that section

being at less-than-ideal orientation. Thus, I also wonder where frac stages may

end on the U part of the lateral. I would think some of the U could host frac

stages.

A good thing

about U-laterals as opposed to multilaterals is that U-laterals do not have

junctions where the multilaterals connect to the main lateral. U-laterals utilize

a single lateral which is less risky for several issues.

Chinook Consulting’s Calin Dragoie wrote about some of the U-laterals in the Permian and Eagle Ford in Texas. The graphics below come from his post. The last two show how a U-shaped well provides ideal spacing if a lateral is drilled between the U.

Below is a graphic by Chinook Consulting where you can see some of the emerging U-lateral spacing and patterns being used in the Delaware and Midland portions of the Permian Basin and some of the companies drilling them.

Shell’s Fishhook Wells Offshore Brunei

In the early 2000s

Shell began drilling fishhook-shaped wells offshore Brunei in order to access

reservoirs from below from an onshore or nearshore drilling site. These are not

horizontal wells but deviated wells designed to reach reservoirs more economically.

The shape is due to the fact that they drill ‘uphill’ to get to the reservoir from

below due to the required geometries for turning the wellbore. This is an

example of optimizing the situation to access reservoirs economically. As noted

in the image below the Brunei reservoirs dip away from the shore.

Multilateral Drilling

Drilling

multilaterals is generally complex and riskier than drilling regular horizontal

wells. The well-funded oil majors have dominated multilateral drilling

globally. Depending on the geological situation they may be the best way to

access and produce the most hydrocarbons. One of the issues with multilaterals

is simply that there are junctions between the main lateral and the smaller lateral

that branch off from it. Each junction can be subject to problems, especially

with drilling and casing. Some multilaterals are just wells with multiple main

laterals of similar length. Others have one main lateral with others branching

off.

Multilateral

well junctions are made using a process known as open-hole sidetracking. This

makes a new branch. Wells drilled horizontally from another horizontal wellbore

are called branches. If a new leg drills out of the horizontal plane to a different

formation it is known as a splay. A guide to multilateral drilling from Drillingmanual.com

gives six levels of junctions. They note:

“The complexity of the multilateral drill depends on

the integrity of the formation, the prevention of water or gas coning, the requirements to

isolate the main wellbore from the laterals, the requirement to reenter each

lateral, and the requirements to isolate production from the laterals.”

Junctions may

be cased or uncased. Cased junctions are better for controlling production. Economics

drives decisions to drill multilaterals. Sometimes there are geological reasons

to drill them such as tapping into different reservoirs from complex fault blocks.

A Level 1 junction has the main wellbore and the lateral left uncased at the junction, as shown below. This is the most common type of junction. The graphic below shows all six levels of junctions.

In a Level 2

junction, the main wellbore is typically cased and cemented, while the lateral,

or at least the junction, is left uncased. This is the second most common type

of junction.

The main

wellbore in a Level 3 junction of multilateral drilling wells technology is

cased and cemented, while the laterals are not cemented but cased only.

A Level 4 junction has both the main wellbore and the laterals cased and cemented, as shown in Figure 2 above.

A Level 5

junction builds upon the Level 4 system by providing pressure integrity at the

junction. The pressure integrity is achieved in the completion by running

tubing and isolation packers.

A Level 6 junction attains full pressure integrity for maximum control. It is explained below and shown in Figure 2:

“Level 6 junction is one in which full pressure

integrity is achieved with the main casing string. There are two types of level

6 junctions: expandable metal junctions and splitter. They are used in new

installations only because the expandable metal junction or splitter must be

run as part of the casing string. The expandable metal junction requires

under-reaming the hole where the junction will be placed to expand the junction

before setting cement. The splitter junction requires drilling a much larger

diameter hole from the surface down to run the splitter. For this reason,

splitters are usually run at shallower depths.”

Canadian Thermal Oil Plays Multilateral Designs:

Fishbone, Feather, and Stacked Multilaterals

The graphics in

this section come from Chinook Consulting Services. They have geosteered many

of these Western Canadian Basin multilaterals wells and are the experts.

In the late 2000s

wells drilled in the Jean-Maie field in Northeastern British Columbia in the Western

Canadian Sedimentary Basin, were commonly drilled as two or three-legged

multilaterals as shown in the map and graphic below. Encana was a main player.

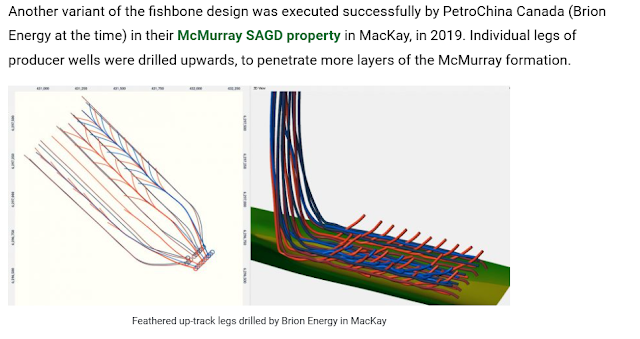

Collector

multilaterals drilled between existing pads of Bluesky wells in the Peace River

oil sands were a precursor to the fishbone and feather multilateral patterns. The

long and straight legs act as collectors and the many shorter lateral legs extend

the drainage area. One well, drilled in 2016 has 47 legs and a total lateral

length of 25,000 meters! Some fishbone and feather designs are shown below.

Stacked laterals

can also be of several types. They can be multilaterals drilled into the same

formation with separate multilateral wells drilling into formations above and/or

below. They can be a single multilateral well that accesses two or more

vertically separated formations. The wine-rack geometry shown below is another type

of stacked lateral where formations are alternated in adjacent legs. As also

shown below, Devon drilled several stacked fishbone designs.

References:

Paperclip

Wells: new well design in the Permian Basin. Calin Dragoie. February 10, 2024. (25) Paperclip Wells: new well design

in the Permian Basin | LinkedIn

Why

Shell Drilled a “Horseshoe” Well in the Permian Basin. Trent Jacobs. Journal of

Petroleum Technology. February 10, 2020. Why

Shell Drilled a “Horseshoe” Well in the Permian Basin

U-lateral

drilling innovations: Making breakthroughs possible for directional projects. Gordon

Feller. World Oil. October 2024. U-lateral

drilling innovations: Making breakthroughs possible for directional

projects

Multilateral

Wells Drilling Technology Full Guide. Drillingmanual.com. August 9, 2021. Multilateral

Wells Drilling Technology Full Guide - Drilling Manual

Drilling

Uphill. Paul Wood. GeoExPro. September 3, 2010. Drilling Uphill - GeoExpro

Multilateral,

Feather, Fishbone: A look at Well Designs in a Mature Basin. Calin Dragoie. Chinook

Consulting Services. October 26, 2020. Well design

in a mature basin • Chinook Consulting

No comments:

Post a Comment