Fuel cells convert

chemical energy into electrical energy. There are many different kinds of fuel

cells and fuel cell chemistry. A protonic ceramic fuel cell is a type of

protonic ceramic cell.

According to

Wikipedia:

“A protonic ceramic fuel cell or PCFC is a fuel cell

based around a ceramic, solid, electrolyte material as the proton conductor

from anode to cathode. These fuel cells produce electricity by removing an

electron from a hydrogen atom, pushing the charged hydrogen atom through the

ceramic membrane, and returning the electron to the hydrogen on the other side

of the ceramic membrane during a reaction with oxygen.”

Source: Wikipedia

Ceramic electrolytes

require high temperatures for efficiency, but lower-temperature fuel cells are

an active area of research.

“PCFCs operating at intermediate temperature of 200 - 400

degrees Celsius have been proposed for heavy duty trucking. Remote power

applications using PCFCs have been demonstrated at Canadian oil wells.”

An April 2023

paper in Electrochimica Acta explains the ongoing research with PCCs and PCFCs.

From the abstract:

“Protonic ceramic cells (PCCs), including protonic

ceramic fuel cells (PCFCs) and electrolysis cells (PCECs), are attracting

increasing attention owing to several advantages such as their low activation

energy for proton diffusion, fuel flexibility, absence of fuel dilution, and

potentially lower housing/stacking costs at intermediate operating temperatures

(400–600 °C). However, one of the major challenges for PCCs is the design and

realization of oxygen electrodes for efficient oxygen reduction and water splitting

reactions. Many research groups have devoted efforts to this research topic and

have obtained encouraging results showing improved power output and current

density in PCCs owing to the improvement of the oxygen electrode. This trend

needs to be continued to enable the commercialization of the PCC technology.

This review article describes the research progress in oxygen electrodes for

PCCs, comprehensively summarizing literature work and offering prospective

pathways for further development of high-performance oxygen electrodes.”

Researchers from

universities in South Korea have announced a breakthrough that has the potential

to double the power output of protonic ceramic fuel cells (PCCs). PCCs are like

batteries, having two electrodes and an electrolyte. I am not going to pretend

to understand the details of fuel cell chemistry or the breakthrough but I will pass on what the

scientists say. An April 2024 paper in Advanced Energy Materials explains the

breakthrough:

“The proton-conducting oxides, widely employed as

electrolytes in ceramic electrochemical cells, exhibit remarkable proton

conductivity that facilitates efficient energy conversion processes. However,

their inherent refractory nature poses a challenge in producing chemically

stoichiometric and physically dense electrolytes within devices. Here a novel

approach is presented, dual-phase reaction sintering, which can overcome the

inherent low sintering ability of the representative BaCeO3-δ‒BaZrO3-δ proton conducting oxides. This approach involves the

simultaneous transformation of a two-phase mixture (comprising fast-sintering

and slow-sintering phases) into a complete single-phase solid solution

compound, along with the densification of the electrolyte, all accomplished

within a single-step heating cycle. During the dual-phase reaction sintering

process, the grains of the fast-sintering phase experience rapid growth owing

to their intrinsic superior sintering ability. Additionally, this growth is augmented

by the Ostwald ripening behavior manifested by the smaller slow-sintering

phase. This synergistic strategy is validated using BaCe0.4Zr0.4Y0.1Yb0.1O3-δ,

and its applicability in electrochemical cells is demonstrated, resulting in a

significant enhancement in performance. These findings offer insights into

streamlining the preparation of refractory ion-conducting ceramic electrolytes

while maintaining their intrinsic properties for practical applications.”

The

dual-phase proton ceramic electrolyte produced by the low-temperature synthesis

process exhibits enhanced sintering characteristics, enabling a reduction in

the sintering temperature of conventional processes. As a result, the intrinsic

properties of the electrolyte can be realized in the device, improving cell

performance. Credit: Korea Institute of Science and Technology

PCCs can potentially be used to improve energy conversion,

resulting in better efficiency, lower cost, and lower energy use.

PCCs “utilize proton (hydrogen ion) transport instead of

oxygen ions, have emerged as next-generation energy conversion devices such as

fuel cells and electrolyzers. Unlike conventional oxygen ion-conducting

electrolytes, PCCs transport the smaller hydrogen ions, enabling higher ionic

conductivity.”

An obstacle to commercializing PCCs has been the high

sintering temperatures required to produce the electrolyte. The new research

has been able to overcome that obstacle. In order to lower that sintering temperature,

the researchers derived a new way to make the electrolyte. Typically, additives

were used to lower the sintering temperature, but those additives remain and

lower the cell’s power density. According to TechXplore:

“The research team discovered that, by synthesizing a

powder containing two different compounds through low-temperature synthesis, a

single compound with excellent sintering properties forms during the sintering

process accompanying the reaction to single phase. This allows the sintering

temperature to drop to 1,400°C without the need for additives.”

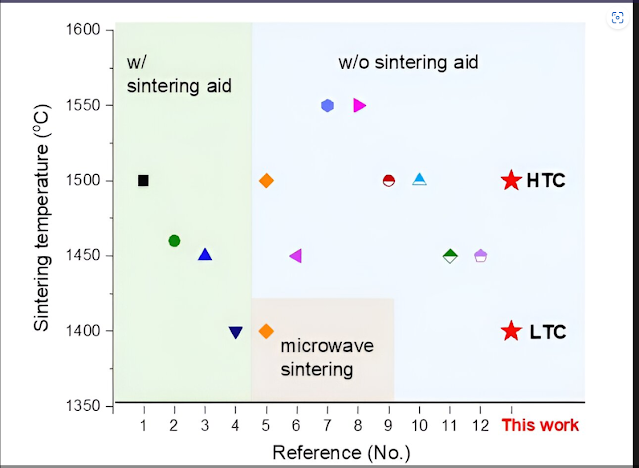

The

new process, which does not use sintering aids or special sintering methods,

achieved the lowest sintering temperature for electrolyte membranes. Credit:

Korea Institute of Science and Technology

Process time,

thermal stability, and performance of ceramic electrolytes are expected to be

improved with the new process.

Dr. Ji of KIST stated, "This research has resolved

the chronic sintering issues in the production of proton ceramic cells. If

large-area technology is successfully developed, it will enable efficient

energy management through green hydrogen production via electrolysis and pink

hydrogen production by utilizing waste heat from nuclear power plants.”

That means the breakthrough can also make electrolysis more

efficient, which could make green hydrogen production less expensive and help

it inch toward more widespread feasibility.

References:

Scientists

make game-changing breakthrough with next-generation power source — here's how

it works. Rick Kazmer. The Cool Down,

November 10, 2024. Scientists

make game-changing breakthrough with next-generation power source — here's how

it works

Protonic ceramic fuel cell. Wikipedia. Protonic

ceramic fuel cell - Wikipedia

Oxygen

electrodes for protonic ceramic cells. Qingjie Wang, Sandrine Ricote, and Ming

Chen. Electrochimica Acta. Volume 446, 1 April 2023, 142101. Oxygen

electrodes for protonic ceramic cells - ScienceDirect

Scientists

develop a new electrolyte synthesis method for next-generation fuel cells. National

Research Council of Science and Technology. TechXplore. October 10, 2024. Scientists

develop a new electrolyte synthesis method for next-generation fuel cells

Dual-Phase

Reaction Sintering for Overcoming the Inherent Sintering Ability of Refractory

Electrolytes in Protonic Ceramic Cells. Junseok Kim, Jiwon Yun, Wanjae Lee,

Do-Hyeong Kim, Puspendu Guha, Jin-Ha Hwang, Deok-Hwang Kwon, Sungeun Yang,

Jong-Ho Lee, Kyung Joong Yoon, Ji-Won Son, Sahn Nahm, Sihyuk Choi, and Ho-Il Ji.

Advanced Energy Materials. April 17, 2024. Dual‐Phase

Reaction Sintering for Overcoming the Inherent Sintering Ability of Refractory

Electrolytes in Protonic Ceramic Cells - Kim - 2024 - Advanced Energy Materials

- Wiley Online Library

No comments:

Post a Comment