Sanitary sewer

systems are considered to be wastewater collection and treatment systems.

Sewers and wastewater treatment systems are considered to be the most common

form of pollution control in the country. Exact specifications for design vary

by state and local jurisdiction. According to an online course in gravity sewer

design based on rules from the State of Florida and Dade County:

“Gravity sanitary sewer systems are a collection of

underground pipes or drains used primarily to convey wastewater from a

community to an authorized point of discharge such as a lift station, pump

station or a wastewater treatment facility.”

“A gravity sanitary sewer system transports wastewater

mainly by gravity along a downward-sloping pipe and it should be designed based

on the pipe size and slope to maintain adequate flow towards the discharge

point without surcharging manholes or pressurizing the system.”

Sewer System Design and Construction

Typical

designs are for gravity sewer sewers but lift pumps, also known as lift stations,

may be employed where gravity drainage is unsuitable due to soil, topography, or

bedrock issues. In addition, there may be pump stations that convey the wastewater

to the treatment plant.

Accurate

estimation of daily wastewater flow rates is very important to sewer system design, and future additions to the system must also be considered. Minimum, average, and peak

daily flow rates are estimated. Peak daily flow rates are used to design for adequate

capacity. Estimating design capacity is typically done by house size or number

of bedrooms for household septic systems. I assume it is done similarly for sewer

lines.

The totality of the drainage area is known as

the tributary area or basin. If there is an addition to an existing sewer

system, then as-built drawings and sewer maps must be consulted. Since drainage

around the buried components of the system may affect those components,

additional information about the water table and soil permeability is

desirable.

The design

period must be considered. Sewer mains and laterals less than 18” can be

designed to last 100 years. Other mains, trunks, interceptors, and outfalls

should be built to last 50-100 years. EPA recommends 50+ years.

It is useful

to derive a ‘design average flow’ rate for the wastewater, in gallons per day (gpd).

This may be the same as the average annual daily flow rate for a system that is

used evenly, or it may be changed to accommodate peak usage where there is increased

seasonal usage. These wastewater flow calculations are important to deriving

the ultimate system size. Population, population density, per capita flows,

residential flows, commercial flows, and industrial flows must all be

considered. Two other important considerations are groundwater infiltration (GWI)

and stormwater inflow. For subsurface wastewater conveyance systems what leaks

in as well as what leaks out must be considered. These extraneous flows, GWI

and inflow, and are commonly known as infiltration/Inflow (I/I) flows. They

must be estimated and added into the flow rate calculations. I/I flows can vary

considerably by system.

The hydraulic

design of the sewer pipe is evaluated based on the size and type of the pipe,

design period, design depth and peak flows. Wastewater flow is of two types: open

channel flow or pressure flow.

“When flow fills the conduit and the Hydraulic Grade

Line (HGL) rises above the sewer crown, the flow is classified as pressure

flow. When the conduit is partially full and the HGL is below the sewer crown

and a freewater surface develops in the sewer, the flow is classified as an

open channel flow.”

Open channel flow is the basis for a gravity sewer system. Hydraulic

slope (S) in sewers refers to the slope of the channel bottom and is the basis

for estimating flow. The types of open channel flow in a gravity sewer system

are steady flow, unsteady flow, uniform flow, non-uniform flow, steady uniform

flow, unsteady uniform flow, steady non-uniform flow and unsteady non-uniform

flow. Steady and unsteady flow refers to the depth of flow being constant flow or

not over time. Uniform and non-uniform flow means that the depth of flow is

constant or not over a location. In steady-uniform flow the depth of flow is

constant with respect to time and location and the hydraulic grade line (HGL)

is parallel to the sewer invert slope. Steady-uniform flow is the default

analysis. “Unsteady uniform flow occurs when the HGL remains parallel to the

sewer invert and fluctuates up and down as the rate of flow fluctuates with

time.” This type of flow is uncommon. Steady non-uniform flow is considered

to be the situation when multiple laterals are entering main lines but is

usually estimated as steady uniform flow.

“Unsteady non-uniform flow develops during the onset and

termination of peak flows. However, design of sewers based on this flow regime

is seldom required, as it involves extensive calculations for flow routing,

wave and water surface profiles.”

The Manning

Equation is used to determine open channel flow characteristics. It was first

presented by Philippe Gauckler in 1867 and re-developed by Robert Manning in

1890.

It is important

to maintain minimum slope and velocity so that solids are not deposited in the

lines. This can help prevent the need for future maintenance due to solids and

sulfides. Adequate velocity helps to keep the pipes clean of solids and greasy

scum and to prevent problems with corrosion and odors caused by sulfides.

“Slope is the key criterion in designing sewer collection

systems to avoid odor and corrosion problems due to sulfides in wastewater.

Sewer systems designed with long runs at minimum slopes are prone to sulfide

generation due to long residence times, poor oxygen transfer, and deposition of

solids.”

“Sewer system design is based on achieving self-cleaning

velocities during normal daily peak flow periods to transport any grit which

may enter the sewer system, scour grease and re-suspended solids that have

settle in sewer during low flow.”

Recommended minimum

slopes from the recommended standards for wastewater flow (RSWF) are given in

the table below.

Minimum velocities for all sewer lines are at 2 ft/sec when “flowing full.” Manning’s formula is applied using an “n” value of 0.013. Daily or hourly peak flows can be estimated. Peak hourly flow rates can be important since the wastewater flows can vary significantly by hour.

System layout

includes the design of the main and trunklines and where to install lift or pumping

stations, if applicable. Surface topography is generally followed where possible

for slope maintenance. Sewer lines typically run through the middle of a street

so that they can more easily collect wastewater from both sides of the street. Other

location issues include location relative to water lines and other utilities, easements,

and rights-of-way. Other considerations include the location of manholes, terminal

cleanouts, service connections, inverted siphons, junction chambers, and other

structures or devices.

Manholes

provide access for observation and maintenance. They are recommended to be at

least 48 inches in diameter by RSWF but the minimum is 24 inches.

“As per RSWF, manholes shall be installed: at the end of

each line; at all changes in grade, size, or alignment; at all intersections;

and at distances not greater than 400 feet for sewers 15 inches or less, and

500 feet for sewers 18 inches to 30 inches, except that distances up to 600

feet may be approved in cases where adequate modern cleaning equipment for such

spacing is provided; As per MD WASD design requirements, manhole to manhole

runs shall be kept in a range no more than 400 feet without permission. Greater

spacing may be permitted in larger sewers.”

The flow channel of a manhole should be constructed to conformable

to that of the flow channel within the sewer main with a similar slope. Manholes

are made of precast or poured concrete. Gasketed flexible watertight connections

are recommended, or any watertight connection arrangement that allows differential

settlement of the pipe and manhole wall to occur. The covers also must be

watertight in order to prevent inflow. If a sewer inflow is 2 ft or higher

above the manhole channel, then a drop manhole is required. A drop manhole

design is shown below. Manholes are typically inspected for damage and

watertightness before the system is activated.

Inverted siphons,

or depressed sewers, are designed to stand full even if there is no flow. The

siphon is designed to “carry the flow under an obstruction such as stream or

depressed highway and to regain as much elevation as possible after the

obstruction has been passed.” They are often constructed with multiple

barrels. Adequate self-cleansing velocities and maintenance flexibility under widely

variable flow conditions are important considerations. The design should permit

cleaning and maintenance.

Sewer connections,

or service laterals, are the pipes that connect individual homes and buildings

to a main sewer line. They are typically 4-, 5-, or 6-inch sewer-grade pipes with

a minimum slope of 2%. Design schematics for shallow and deep laterals are shown below.

Equalization storage tanks may be installed

where peak flow rates may exceed design capacity. The tank contents collect wastewater

during peak flow and feed it back into the sewer pipe system during times of

lower flow. Sewer lines must be installed deep enough to prevent freezing and

to accommodate wastewater from basements. Pipes are typically different grades

of plastic such as PVC but may also be iron-based, cement, concrete, or vitrified

clay. Plastic pipes are more flexible.

Corrosion due

to hydrogen sulfide (H2S), other sulfides, and sulfuric acid can be a problem for

sewer pipes. Metal pipes are more susceptible so may need corrosion-resistance

measures.

Stream

crossings should be minimized and where used should be perpendicular to stream

flow and have no gradient. They must be at least 1 foot below the base of the stream

where it cuts rock, 3 feet below the base of the stream where there is soil, and

more than 3 feet if it is a wide stream.

Sewer pipes

must be at least 6-12 inches away from water main lines and preferably more. Any

connections between pipes must be as far away from the water main as possible. Structural

support may be required where sewer and water lines cross. The water or sewer

lines may be required to either be encased in a watertight sleeve or the sewer

pipe must be constructed to the standards of water pipe and be pressure tested

to 150 psi.

Construction may

have to contend with high water tables which can make pipes buoyant.

Watertightness is a factor for any pipe joints and service connections. There

are also requirements for making the trenches, bedding the pipes, and backfilling

around them. The ultimate goal of these measures is to prevent infiltration and

root penetration.

“As per RSWF, deflection tests shall be performed on all

flexible pipes. The test shall be conducted after the final backfill has been

in place at least 30 days to permit stabilization of the soil-pipe system.”

“No pipe shall

exceed a deflection of 5 percent. If deflection exceeds 5 percent, the pipe

shall be excavated. Replacement or correction shall be accomplished in accordance

with requirements in the approved specifications.”

“As per MD-WASD standards, the deflection, or deformation

of the pipe due to external loading, shall not exceed approximately 7.5

percent. Deflection shall be determined by passing an approved go/no go mandrel

through the gravity sewer main. Deflection will be based on the average inside

diameter as presented in ANSI/AWWA C900.”

A lamping test uses

light:

“For lamping test, each section of installed sewer lines

shall show, from each end, a full circle of light.”

Leak Detection

Water and air

pressure may be utilized to determine leakage rate.

“As per RSWF, the leakage exfiltration or infiltration

shall not exceed 200 gallons per inch of pipe diameter per mile per day for any

section of the system. An exfiltration or infiltration test shall be performed

with a minimum positive head of 2 feet.”

A sewer system is

recommended to be pumped out before an infiltration test is performed. Pumping

into or out of calibrated drums is the recommended method for infiltration and

exfiltration testing.

The water level for testing

should provide a minimum head of 2 feet in a lateral connected to the test

portion, or, in the event there are no laterals in the test or a minimum

difference in elevation of 5 feet between the crown of the highest portion of

the drain or sewer and the test level.

“Where infiltration or exfiltration exceeds the allowable

limits specified herein, the defective pipe, joints, or other faulty

construction shall be located and repaired.”

Air pressure

tests may also determine leakage rates. Procedures vary by pipe material.

“As per RSWF, the air test shall, as a minimum, conform

to the test procedure described in ASTM C 828 for clay pipe, ASTM C 924 for

concrete pipe, ASTM F 1417 for plastic pipe, and for other materials test

procedures approved by the regulatory agency.”

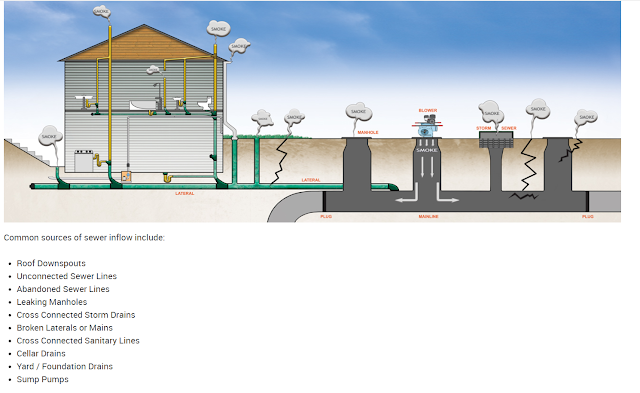

Smoke Testing for Leak Detection

Smoke testing may

be done to find leaks and even to locate lost manholes. A smoke test uses

non-toxic smoke and high-capacity blowers to blow smoke through the sanitary

sewer pipes. Pumping smoke down through the sewer line can be used to locate

leaks. The smoke can enter people’s houses and reveal system leaks within the

house. If there are no leaks the smoke will exit via the house plumbing vents.

Finding plumbing leaks is secondary to the main goal which is to find leaks in

the public part of the sewer system. Typically, a section of the sewer system

is plugged off and workers walk around the neighborhood looking for smoke. It

is best to prepare for a smoke test.

“Prior to testing date, pour ½ gallon of water in all

basement floor drains or seldom used sink/shower drains and be sure to flush

any seldom used toilets. This ensures

that drain traps are filled with water and smoke will not enter the house

through any normal, working sewer-line connections. This “traps” water in the

pipes, and is called “filling your traps.”

Below is shown a smoke test planned for this week in a town

in West Virginia.

Sewer Lateral/Service Connection Inspection

I have a little

bit of experience inspecting sewer lateral connections in small-town sanitary sewer

additions. We would go out to each house connection before the contractor

covered up the new connection. These are usually 4-inch lines going into an 8-inch

or larger main sewer line, or sewer main. We would record the drop from the house

to the main sewer line. We would make sure the proper sewer line was used. We

would note and GPS any nearby manholes we found. We would note where the sewer

line went into the house, where it met the main sewer line, and the location of

the cleanout line to the surface, usually close to the house. We would do a water

test with a bucket of water to confirm water was flowing down the lateral. We

would do an air pressure test which involves plugging off both ends of the line

and observing whether the pressure was sustained without dropping. On the near

end, a device called an inflatable pipe plug balloon plug, pipe pressure test plug,

plumbing test ball, and sewer test plug with a pressure gauge was attached, and

the pressure was increased to about 3.5 psi for about 2.5 minutes. If there was

no drop in pressure, the test would be good. This is an easy way to do leak

detection on a short section of sewer lateral. Other states, localities, and

situations may require different pressure drop limits. We would also sketch a

drawing to indicate the house, the lateral, the main line, and any nearby manholes,

if applicable. Typically, it was a short and non-complicated process.

We also permitted the laterals. In addition to

the new laterals, there would often be existing household sewage systems, or septic

systems, that would now be required to be abandoned. This involves getting an

abandonment permit, having the septic tank pumped out, crushing it inward,

filling the space with gravel, and covering it over with topsoil.

References:

Smoke

Testing Sewers in Your Community. Information Flyer. Thrasher Group and Town of

Elizabeth. November 2024.

Gravity

Sanitary Sewer Design and Construction. Second Edition. Prepared by a Joint

Task Force of the Environmental and Water Resources Institute and the Pipeline

Division Committee on Pipeline Planning of the American Society of Civil

Engineers and the Collection Systems Subcommittee of the Technical Practice

Committee of the Water Environment Federation. Edited by Paul Bizier.

ASCE Manuals and Reports

on Engineering Practice No. 60 WEF Manual of Practice No. FD-5. 2007. Front Matter

Gravity

Sewer Design. PDH online Course C606 (8 PDH). Instructor: Jorge Acevedo, PE. 2020. Gravity Sewer Design

Manning

Formula for Determining Open Channel Flow. OpenChannelFlow.com. Manning

Formula for Determining Open Channel Flows | Open Channel Flow

Municipal

Wastewater. U.S. EPA. Municipal

Wastewater | US EPA

Primer

for Municipal Wastewater Treatment Systems. U.S. EPA. September 2015.

Primer

for Municipal Wastewater Treatment Systems

Smoke

Testing: What Homeowners Need to Know. Superior Smoke. Smoke

Testing: What Homeowners Need to Know

No comments:

Post a Comment