Water purification

refers to the removal of undesirable chemicals, biological contaminants,

suspended solids, and gases from water. It is typically purified for drinking

water but may be purified to different standards for medical, pharmacological,

chemical, and industrial purposes. Water may be filtered, and stilled for sedimentation

to reduce suspended solids, flocculated, chlorinated, and/or run through ultraviolet

(UV) light to purify it. Confirmation of water quality is determined by chemical

and microbiological testing, which, unfortunately, is relatively costly.

Water treatment

plants typically pre-treat the water through pumping and

containment, screening out any large debris (not needed for most groundwater), storage

for biological purification, and running through slow sand filters.

Pre-chlorination to kill off any bacterial fouling of the incoming pipes has

largely been discontinued as a pretreatment method due to the harmful

byproducts of chlorination. It is still used sometimes to remove algae. Slow

sand filters capture some contaminants and allow for biological treatment as

the water runs through them very slowly. In alluvial groundwater aquifers that

occur in subsurface unconsolidated river sands (alluvium), the natural flow of

the water through the sand acts as a slow sand filter for the river water. Those

aquifers are considered to be younger groundwater since the water filtered down

through the alluvium from the river over a few years or decades. Slow sand

filters are also used to treat water in swimming pools where the water is

continuously filtered slowly through a large drum filled with sand. These must

be replaced every so often as the pressure changes due to solids buildup.

Aeration

is often used to treat water. Packed Tower Aeration utilizes tall towers and

can remove VOCs, disinfection byproducts, CO2, H2S, and other organic

compounds. Multi-stage bubble aeration can remove the same compounds but is

less efficient than packed tower aeration. However, it may be cheaper and more

applicable to smaller water systems.

pH

adjustment is an important water treatment technology. If the source

water is too acidic then lime, soda ash, or sodium hydroxide (caustic soda) may

be added to raise the pH to neutral (7). The addition of lime will increase the calcium

ion concentration and the water’s hardness. Removal of dissolved gases with

degasifiers is another method of raising water pH. Making the water slightly

alkaline aids the coagulation and flocculation process. It also limits the

leaching of lead from pipes and solders as occurs with more acidic water

sources.

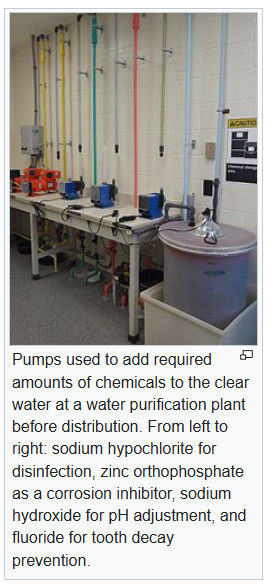

Corrosion control

via phosphate feeds is another water treatment step in some systems

that are deemed in need of it. Phosphoric acid, zinc orthophosphate, or other

compounds may be added to treat the water. These compounds can remove orthophosphates

that are “believed to combine with lead and copper in plumbing materials to

form insoluble compounds, thus reducing lead and copper release at the tap.”

Coagulation

and flocculation are the next steps in water treatment. Coagulation

involves the addition of coagulants such as aluminum sulfate (alum) or iron III

salts such as iron III chloride. Through physical and chemical processes this causes

precipitation and then merging with suspended solids particles in the water

which can be flocculated out. Suspended solids in water may include inorganic

clay and silt particles, algae, bacteria, viruses, protozoa, and natural organic

matter. Coagulation and flocculation are considered to be two parts of the same

overall process. In the 1960s polymers were developed to aid flocculation and

in some cases to replace the inorganic metal salt coagulants. Polydiallyldimethylammonium

chloride (polyDADMAC) is a commonly used polymer to aid flocculation.

Sedimentation

in a sediment basin is the next step after flocculation. Here the water

clarifies as the floc settles to the bottom of the basin. The upper part of the

water is the clearest and is passed on over a weir. Overflow rates from

sedimentation tanks are typically 0.5 to 1.0 gallons per minute per square foot.

The tanks must be dep enough so that the water movement does not disturb the

floc, or sludge that falls to the bottom. This sludge, which typically makes up

3 to 5 % of the total water volume must be periodically removed and treated. Typical

detention times are 1.5 to 4 hours and typical sedimentation tank depths are 10

to 15 feet. Sludge treatment and disposal can get expensive for water treatment

plants. Other clarification methods are Lamella clarifiers which involve

inclined plates and tubes to increase the surface area so more particles can be

removed, and floc blanket clarifiers which remove sediment by trapping it in a

layer of suspended floc as the water is forced upward.

Dissolved

air flotation utilizes pressurized air that makes bubbles when it returns

to atmospheric pressure and those bubbles trap suspended solids. It is used

where normal sedimentation in tanks is considered to be inadequate. In this

method, the floc floats on the surface and is skimmed off while the clarified

water below is transferred to the next step in the treatment process which is filtration.

Filtration

can involve the use of one or more of several types of water filters. Filtration

can capture many of the pathogens, providing some disinfection, but some still

get through the filters. The most common type of filter is a rapid sand filter.

These have vertical layers of sand and an activated carbon layer at the top to

filter out organic compounds that affect taste and odor. The filter is periodically

cleaned by reversing the flow or backflushing. Compressed air may be used as

well. Pressure filters are employed by some water companies where the filter

medium is enclosed in a steel casing under pressure.

Advantages {of pressure filters}

·

Filters out much smaller particles than paper

and sand filters can.

·

Filters out virtually all particles larger

than their specified pore sizes.

·

They are quite thin and so liquids flow

through them fairly rapidly.

·

They are reasonably strong and so can

withstand pressure differences across them of typically 2–5 atmospheres.

·

They can be cleaned (back flushed) and reused

Slow sand filters

require space and land as water moves slowly through them. They rely on

biological treatment more than physical filtration. They utilize graded layers

of sand with the finest at the top. Wikipedia via a 2014 article in Water

Supply describes more interesting things about slow sand filters:

“Filtration depends on the development of a thin

biological layer, called the zoogleal layer or Schmutzdecke, on the surface of

the filter. An effective slow sand filter may remain in service for many weeks

or even months, if the pretreatment is well designed, and produces water with a

very low available nutrient level which physical methods of treatment rarely

achieve. Very low nutrient levels allow water to be safely sent through

distribution systems with very low disinfectant levels, thereby reducing consumer

irritation over offensive levels of chlorine and chlorine by-products. Slow

sand filters are not backwashed; they are maintained by having the top layer of

sand scraped off when the flow is eventually obstructed by biological growth.

Slow Sand Filtration

Bank filtration

involves using the sediments in a riverbank as a kind of sand filter or alluvium as shown

below.

Microfiltration such as ultrafiltration

membrane filtration, or the chemical method of ion exchange can

remove dissolved ions. Activated carbon filters can remove organic chemicals and

chlorine. Nanofiltration (NF) uses semi-permeable membranes to

separate and purify water by removing particles and solutes with a molecular

weight between 200 and 1,000 daltons. Nanoscale graphene-based filters can

remove just about anything while letting the water molecules pass through. Water

softeners typically employ ion exchange to remove calcium and magnesium ions, replacing

them with sodium and potassium ions. This is cation exchange since the elements

are positively charged ions. Anion exchange utilizes negatively charged ions

(anions). It can remove arsenic, chromium-6, cyanide, nitrate, perchlorate,

per- and polyfluoroalkyl substances (PFAS), sulfate, and uranium. Deionization via

ion exchange is sometimes employed following reverse osmosis with the product

being high-purity deionized water. Ion exchange can also remove nitrates,

arsenic, and heavy metals. Granular activated carbon filters are made from

coal, peat, wood, or coconut shells. These filters can remove inorganic

contaminants including antimony, arsenic, beryllium, fluoride, selenium,

thallium, and uranium. They can also remove organic compounds, including those

that affect taste and odor as well as disinfection byproducts and VOCs. Contaminants

are trapped by adsorption

Disinfection

is the next step which kills off any remaining pathogens. Possible pathogens

include viruses, bacteria, including Salmonella, Cholera, Campylobacter, and

Shigella, and protozoa, including Giardia lamblia and other cryptosporidia. Disinfection

is often done in a disinfection tank where the water is held to achieve

sufficient ‘contact time’ with the disinfectant at the desired concentration.

Chlorine compounds are commonly used for disinfection. These may include chloramine,

chlorine dioxide, sodium hypochlorite (bleach), or calcium hypochlorite. Unfortunately,

chlorine compounds yield potentially harmful byproducts. These include trihalomethanes

(THMs) and haloacetic acids (HAAs). Both are carcinogenic in large quantities

and are regulated by the EPA. Chlorine dioxide can detonate. It is fast-acting

but yields chlorite as a byproduct that is regulated to low levels. Chloramines

are being used more often since they don’t make THMs and HAAs, but they are

less potent than sodium hypochlorite. Chloramines derive from ammonia and

chlorine. They can also experience nitrification with the end results being undesirable

nitrates. They can also leach metals, including lead. Chlorine compounds have

limited effectiveness against pathogenic protozoa that form cysts in water such

as Giardia lamblia and Cryptosporidium.

Ultraviolet

light (UV) is most effective at inactivating cysts, in low turbidity

water. It is less effective in water with turbidity. It can work well in concert

with chloramines. UV light can be used in conjunction with hydrogen peroxide

and/or chlorine which create radicals such as hydroxyls that can oxidize

contaminants. It can remove dangerous microcontaminants such as 1,4-dioxane,

N-nitrosodimethylamine (NDMA), and methyl tert-butyl ether (MTBE).

Solar UV

radiation is also used in water disinfection. Ionizing radiation, bromine, and

iodine are minor methods of disinfection. Fluoride is often added to water at

very low concentrations to reduce tooth decay. Small amounts of phosphate ions

may be added to raise pH in order to prevent the leaching of lead from pipes, which

is known as plumbosolvency. In a few groundwater sources radium is removed via

ion exchange. Sometimes natural fluoride levels in water are too high and it is

removed via activated alumina and bone char filtering.

Boiling water removes

some pathogens. Adsorption with granular activated carbon removes many organic

compounds and their tastes and odors. Home water filters and fish tanks utilize

activated carbon. Metallic silver nanoparticles may also be used. They are

anti-bacterial and can remove pesticide residues. Filtered water from these

filters should be used quickly and the filters should be replaced regularly.

Biological

treatment of drinking water uses indigenous bacteria to remove

contaminants. According to the EPA:

“The process has a vessel or basin called a bioreactor

that contains the bacteria in a media bed. As contaminated water flows through

the bed, the bacteria, in combination with an electron donor and nutrients,

react with contaminants to produce biomass and other non-toxic by-products. In

this way, the biological treatment chemically “reduces” the contaminant in the

water.”

It can remove

nitrates and perchlorates. It destroys contaminants so there is no need for

contaminant removal.

Distillation

can remove 99.9% of contaminants by recondensing the vapor from boiling water

but contaminants with higher boiling points can get through.

Reverse

osmosis is a common way to get high-purity water. It is often used in

conjunction with nanofiltration. According to Wikipedia via Puretec Water:

“Reverse osmosis involves mechanical pressure applied

to force water through a semi-permeable membrane. Contaminants are left on the

other side of the membrane. Reverse osmosis is theoretically the most thorough

method of large scale water purification available, although perfect

semi-permeable membranes are difficult to create. Unless membranes are

well-maintained, algae and other life forms can colonise the membranes.”

Reverse osmosis

may be single pass, double pass, or a combo of both. It is a process that is both

water-intensive and energy intensive.

Other methods

are used to treat contaminated water such as crystallization into hydrates with

low molecular weight gases such as CO2. The water is then separated from the

hydrate crystals. In situ chemical oxidation (ISCO) involves injecting

oxidizers into contaminated soil or groundwater. Bioremediation utilizes microorganisms

to remove contaminants such as alkanes, perchlorates, and metals. It is also

used for contaminated soil and groundwater. Hydrogen peroxide (H2O2) is very

good at disinfecting water. It can be delivered from chemical plants but is

apparently much more potent if made onsite utilizing a gold-palladium catalyst to

make the H2O2 from ambient hydrogen and oxygen. It is very good at killing E.

coli bacteria.

Distilled, or demineralized

water may upset a person’s natural fluid balance. It increases the elimination

of electrolytes. There are recommendations for safe, ideal, and non-safe magnesium

concentrations, calcium concentrations, and water hardness. High water hardness

has been linked to increases in gallstones, kidney stones, urinary stones,

arthrosis, and arthropathies.

Emerging water

treatment technologies include improvements in nanotechnology, advanced

oxidation processes (AOPs), electrocoagulation, forward osmosis for salt

removal, membrane distillation, biological nutrient removal to remove nitrogen and

phosphorus, carbon nanotube filters, solar desalination, microbial fuel cells

which use particles in water to make electricity, and emerging

nanomaterials.

Portable and Home Water Treatment

Home water

filtration systems utilizing activated charcoal are now very common. For

instance, I have a Brita filter. One new trend in portable water treatment is

electric water pitchers. These work well but the filters need to be replaced every

200 gallons or every three months, and the filters cost from $20 to $60. Thus,

this is mainly a solution for those who can afford it.

Safe and Clean Drinking Water for People Who Need

It and New Ways to Help

Millions or

even up to 2 billion people around the world still lack access to safe and

clean drinking water. The problem is most prevalent in rural areas where people

get water from rivers, lakes, or hand-dug wells. One emerging solution utilizes

an aluminum foil coated with a special material called layered double hydroxide

(LDH). This material acts like a magnet, attracting and trapping microbes. It was

developed by an environmental engineer. It is being touted not as a standalone

treatment but as a complementary one that is inexpensive and fast-acting.

“In laboratory tests we found the LDH foil remarkably

efficient, removing over 99% of E. coli bacteria, a common indicator of water

contamination, from water samples within a few hours. We found that its

efficacy also extends beyond E. coli, targeting a wide range of waterborne

pathogens, including bacteria, viruses and parasites. This means that the LDH

foil offers comprehensive protection against various diseases.”

The process

relies on “electrostatic attraction, drawing the microbes towards the LDH

foil like iron filings to a magnet. Other chemical and physical forces

contribute to making pathogens bind to the LDH surface, ensuring their

effective removal from the water.”

This solution is

looking promising for use in Africa where there is a need for clean water

access. The LDH foil can be provided for less than $7 per person annually. More

research is needed, and field trials are underway for this emerging inexpensive

clean water solution.

Nanoconfined Single Atom Catalysts (SACs) – New Research

for Advanced Oxidation Processes Looks Promising but Still Needs Tweaked

New research from

a paper in Nature is improving the technique of advanced oxidation processes

(AOPs) via nanoconfined single-atom catalysts. According to Tech Xplore:

“This new method resulted in an astonishing 34.7-fold

increase in the rate of pollutant degradation compared to traditional methods.

The efficiency of oxidant use also improved significantly, from 61.8% to 96.6%.

The system proved to be highly effective in degrading various electron-rich

phenolic compounds, demonstrating robustness in different environmental

conditions and maintaining high performance in real lake water tests.”

According to the

paper’s abstract:

“The introduction of single-atom catalysts (SACs) into

Fenton-like oxidation promises ultrafast water pollutant elimination, but the

limited access to pollutants and oxidant by surface catalytic sites and the

intensive oxidant consumption still severely restrict the decontamination

performance. While nanoconfinement of SACs allows drastically enhanced

decontamination reaction kinetics, the detailed regulatory mechanisms remain

elusive.”

References:

Study

reveals new catalytic pathway for efficient water pollution control. Science X

staff. Phys.org. August 27, 2024. Study reveals new catalytic pathway

for efficient water pollution control (msn.com)

Nanoconfinement

steers nonradical pathway transition single atom fenton-like catalysis for

improving oxidant utilization. Yan Meng, Yu-Qin Liu, Chao Wang, Yang Si,

Yun-Jie Wang, Wen-Qi Xia, Tian Liu, Xu Cao, Zhi-Yan Guo, Jie-Jie Chen &

Wen-Wei Li. Nature Communications volume 15, Article number: 5314 (2024), Nanoconfinement steers nonradical

pathway transition in single atom fenton-like catalysis for improving oxidant

utilization | Nature Communications

Water

purification. Wikipedia. Water purification - Wikipedia

Water

treatment. Wikipedia. Water treatment - Wikipedia

The

Future of Water Purification Technology, Water Filter Direct. Blog. July 19,

2023. Revolutionary Leap: Water

Purification Technologies Reshaping Our Future – Water Filter Direct

Emerging

Trends in Water Purifier Technology: 2023. Drink Prime. Latest Water Purification and

Filtration Technology (drinkprime.in)

Safe

Drinking Water Act: Overview of Drinking Water Treatment Technologies. U.S.

EPA. Overview of Drinking Water Treatment

Technologies | US EPA

Aluminum

foil that can clean water—researchers develop coating that attracts and traps

dangerous microbes. Taufiq Ihsan. TechXplore. September 2, 2024. Aluminum foil that can clean

water—researchers develop coating that attracts and traps dangerous microbes

(msn.com)

Tap

into technology: New innovations in water filtration systems. Yackulic

Khristopher. Android Headlines. August 26, 2024. Tap into technology: New innovations

in water filtration systems (msn.com)

Influence

of operating parameters on the performance of a household slow sand filter. Abhilash

T. Nair; M. Mansoor Ahammed; Komal Davra. Water Supply (2014) 14 (4): 643–649. Influence

of operating parameters on the performance of a household slow sand filter |

Water Supply | IWA Publishing (iwaponline.com)

The

Basics of Reverse Osmosis. Puretec. The

Basics of Reverse Osmosis | Puretec Industrial Water (puretecwater.com)

No comments:

Post a Comment