An injection well

is a well that injects fluids underground to be stored in porous geologic

formations. The injection zones may be deep sandstones or limestones or shallow

soil layers. Injected fluids may be water, wastewater, brine (salt water), or

water mixed with chemicals. For underground injection control (UIC) purposes a

well may be defined as a drilled borehole or as a dug hole, an improved

sinkhole, or a subsurface fluid distribution system. EPA notes:

“Injection well construction is based on the type and

depth of the fluid injected. For example, wells that inject hazardous wastes or

carbon dioxide (CO2) into deep isolated formations have sophisticated

construction. These wells are designed

to provide multiple layers of protective casing and cement. In contrast,

shallow wells are usually of simple construction.”

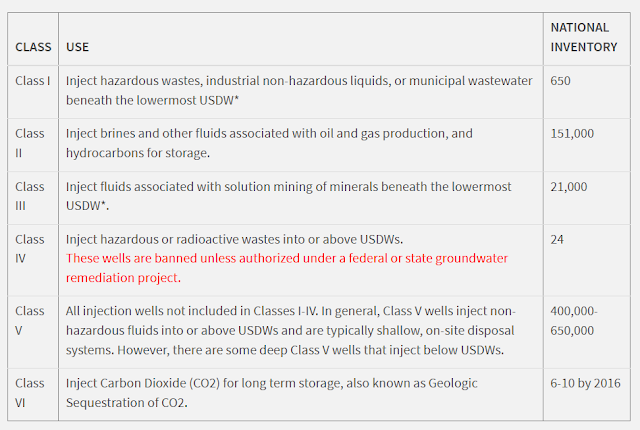

UIC wells are classified into six types based on depth, type

of injection, and the risk to drinking water aquifers. Injection wells are used

to store CO2, dispose of waste, enhance oil production, mine water disposal, solution mining, and prevent saltwater intrusion. In the 1930s the

practice became widespread to dispose of oilfield brines. In the 1950s

industrial wastewater from chemical companies began to be disposed of

underground.

EPA regulates UIC

wells according to the 1974 Safe Drinking Water Act (SDWA). That law mandated

them to develop safe practices and minimum standards for UIC wells in order to

protect underground sources of drinking water (USDW) from contamination. The

UIC program works in accordance with local and regional groundwater protection planning.

“The purpose of the UIC requirements is to ensure that

either:

·

Injected fluids stay within the well and the

intended injection zone

·

Fluids that are directly or indirectly

injected into a USDW do not cause a public water system to violate drinking

water standards or otherwise adversely affect public health.”

This is important because it is well known that fluids can migrate underground at vastly different rates depending on the geologic conditions. Injection well oversight is provided by states that are given primacy by the EPA or by the EPA through one of their regional offices. Currently, there are 33 states that have been given primacy to regulate underground injection. More than 740,000 injection wells were regulated by the UIC program in 2018. Some basic info and data is given below. The third graph below shows that Class II wells are inspected the most. The fourth graph shows that most Class V wells are not permitted but mostly documented older wells (if I am reading that right) so Class II wells make up the bulk of permits.

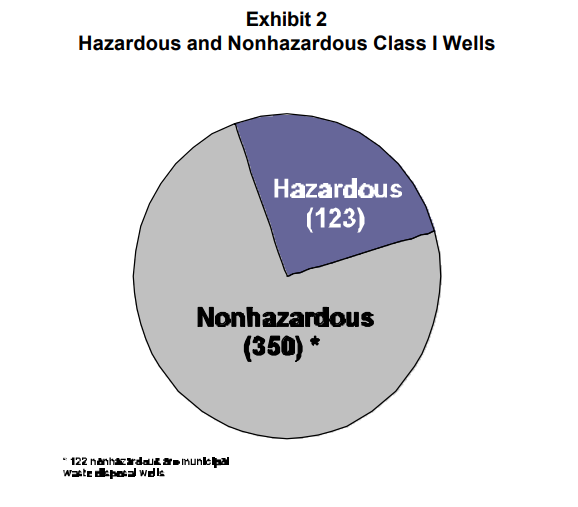

Class I: Industrial and Municipal Waste Disposal Wells

Class I wells can

inject both hazardous (17%) and non-hazardous (53%) wastes. These wastewaters

are injected into deep confined geologic reservoirs. Wastewater from petroleum

refining, metal production, chemical production, pharmaceutical production, commercial

disposal, food production, and municipal wastewater treatment are injected into

Class I UIC wells. Wastes defined as hazardous are also regulated under the Resource

Conservation and Recovery Act (RCRA). About 17% of Class I wells are hazardous

waste disposal wells. Most are located at industrial facilities and dispose of

waste generated onsite. They are operated in 10 states with the majority in

Texas and Louisiana. Only a few commercial Class I wells accept hazardous waste

generated offsite. There are about 800 class I injection wells in the U.S. Due

to geological suitability, most of these are along the Gulf Coast or along the Great

Lakes. There are non-hazardous class I UIC wells in 19 states. Most are in Texas,

California, Louisiana, Kansas, and Wyoming. About 30% of class I UIC wells are municipal

wastewater disposal wells located in Florida. Typical depth ranges for Class I

wells are 1700 ft to greater than 10,000 ft.

“Every Class I well operates under a permit. Each permit

is valid for up to 10 years. Owners and operators of Class I wells must meet

specific requirements to obtain a permit. These requirements address the

siting, construction, operation, monitoring and testing, reporting and record

keeping, and closure of Class I wells.”

The sections below from the 2001 study of Class I UIC well

risks summarize the construction, operation, monitoring and testing, reporting

and record keeping, and closure requirements of Class I wells.

Class II: Oil and Gas Related Injection Wells

Class II UIC

wells primarily inject oil and gas brines. It is estimated that over 2 billion gallons

of oil and gas wastewater are injected into Class II wells daily. In this case, the waste came from the ground, being produced along with oil and gas and so it

is basically being put back into the ground, though many times in a different

geological formation and depth than from where it originated. Texas,

California, Kansas, and Oklahoma have the most Class II injection wells. There

are about 180,000 Class II wells in the U.S. There are three basic types: 1)

disposal wells, 2) enhanced recovery wells, and 3) hydrocarbon storage wells. Brine

disposal wells make up about 20% of Class II wells. Enhanced recovery wells,

where water is injected to help recover oil from reservoirs, make up nearly 80%

of Class II wells. There are about 100 hydrocarbon storage wells in the U.S. Most

of these are in the Strategic Petroleum Reserve.

Oil and gas

brines are toxic due to high salinities, often greater than seawater, and the

presence of toxic heavy metals and low-level radioactivity. As with Class I

wells there are requirements for permitting, construction, conversion, operation,

monitoring and testing, inspections, reporting, record keeping and closure.

Well operators

are required to submit maps, area of review plans, corrective action plans, a

schematic of the proposed well, landowner information, geological data, a

formation testing plan, construction and conversion procedures, an operating

and monitoring plan, a plugging and abandonment plan, financial assurance, a site

security plan, manifest requirements, and existing EPA permits.

Modern oil and

gas wastewater injection wells may inject high volumes at high pressures. This

is determined based on geology and mechanical reservoir properties. This has

led to some serious issues with oil and gas wastewater injection. There are three

major problems: 1) induced seismicity, 2) migration of injected fluids into

nearby oil and gas reservoirs, and 3) migration via surface spills or casing

leaks that may affect drinking water aquifers. Injecting wastewater into

reservoirs that are connected to fault systems can lead to induced seismicity,

or earthquakes, by helping known and unknown faults to slip. These types of

shallow earthquakes are rarely damaging but there are some cases of property

damage and lawsuits. Number 2, the migration of injected fluids into nearby oil and

gas reservoirs, is also accelerated by high injection volumes and pressures.

There are some cases in Southeastern Ohio where this is documented. The issue

is mainly economic as nearby gas producers say the water, which was injected in

the gas reservoir, was chemically identified and tied to the injection wells,

is lowering the gas production in their wells. In that case, water migrating faster

through fracture systems is a likely scenario. Number 3, migration via surface

spills or casing leaks above an aquifer, is the highest risk scenario. Some Class

II disposal wells handle a high volume of wastewater. More water means more

opportunities for spills. Often old wells are converted into Class II disposal wells.

Sometimes, they may develop well integrity issues. This is what happened in a

gas storage well at Aliso Canyon on California that experienced a dangerous gas

leak in 2015. The well was drilled in the 1950s and later converted into a gas

storage field production well. It was later determined that there was a shallow

casing leak that leaked the gas. Since Class II wells are usually much deeper

than any freshwater aquifers there is little possibility of gas migrating up into

an aquifer from below. Contamination is far

more likely from a surface spill or if there is a casing leak above the

aquifer. Casing leaks are rare but less so with older wells. The presence of

H2S inside or outside the borehole can corrode the casing over time. Some water

is corrosive. Early in the Marcellus shale gas play in Northeastern

Pennsylvania, there were wells that would find sustained casing pressure in the annulus, indicative of “stray gas” migration. Some thought the gas had migrated

up from deep reservoirs such as the Marcellus, but it was chemically proven

that the stray gas came from gas zones just below the aquifer. Better well

cementing has led to far fewer stray gas incidents. The biggest danger from the

gas is its flammability. It must be vented for safety if it is above the

threshold concentration. There is generally no contamination risk.

The use of diesel fuel in hydraulic fluids

also requires Class II well permitting. I believe this is currently very rare

to non-existent although it was practiced in the past. In the Energy Policy Act of

2005, hydraulic fracturing received a broad exemption under the SDWA, with the

exception of diesel fuel.

Class III: Injection Wells for Solution Mining

In Class III

UIC wells fluids are injected to dissolve and extract minerals. Solution mining

involves injection wells and production wells. Wells that produce brine for surface

extraction are not regulated under the UIC program, only wells that inject.

Many wells do both and are regulated as Class III wells. Uranium, salt, copper,

and sulfur are produced through solution mining. More than half of all salt

mining and 80% of uranium mining is done through Class III UIC wells.

Most Class III

wells in the U.S. are uranium in-situ leaching (ISL). The leaching process

involves injecting a solution known as a lixiviant. The lixiviant dissolves the

uranium ore after sufficient contact time. Then the resulting fluid is produced

to surface, the lixiviant is separated from the uranium and reinjected to dissolve

more ore.

Salt solution

mining wells inject water to dissolve the salts with the resulting brine being

produced to the surface. There are two main methods: 1) injecting through the tubing

and producing through the annular space between the tubing and the production

casing. This is a single well method. 2) if the salt occurs in a dome a single

well is used but if the salt occurs in separated layers, then multiple wells injection

wells are used. Copper solution mining occurs in a few states where a sulfuric

acid solution is injected to dissolve the copper. Sulfur solution mining wells

may occur where super-heated steam makes a sulfur solution that can be produced

through the Frasch process. Currently, there are no wells injecting for sulfur

solution mining. In solution mining more fluid is extracted than injected,

according to EPA, apparently to prevent fluid migration that could impact drinking

water. It is not uncommon for benign fluids to be injected into underground

sources of drinking water (USDW). This is often true for uranium ISL which taps

sandstone groundwater aquifers. Solution mining, especially salt solution

mining, can cause subsidence in overlying aquifers. Additional requirements

include tubing that can accommodate the injected fluids, cementing to prevent fluid

migration into a USDW, pre-injection pressure testing, monitoring flow rate and

pressure, casing testing every five years, and adequate plugging and

abandonment.

Class IV: Shallow Hazardous and Radioactive

Injection Wells

The EPA explains

Class IV UIC wells:

“Class IV wells are shallow wells used to dispose

hazardous or radioactive wastes into or above a geologic formation that

contains an underground source of drinking water (USDW). In 1984, EPA banned

the use of Class IV injection wells. These wells may only operate as part of an

EPA- or state-authorized ground water clean-up action. Less than 32 waste

clean-up sites with Class IV wells exist in the United States.”

Both Class IV and Class V wells inject fluids into or above

USDW. If a Class V well injects hazardous fluids, it becomes a Class IV well. Both

classes may include septic systems or dry wells. Class IV wells are wells that

are used to clean up groundwater contaminated by hazardous chemicals. A common

method of treatment is the pump-and-treat method where groundwater is pumped to

the surface for treatment and then injected back into the aquifer over and over

until the contaminant level drops to acceptable levels or until no more

treatment is possible. Non-hazardous waste wells also use this method of groundwater

remediation.

Class V: Wells for Injection of Non-Hazardous Fluids

into or Above Underground Sources of Drinking Water

Class V UIC wells are wells that are left over from the other classifications and may include aquifer storage and recovery wells, geothermal electric power wells, or deep injection wells for salinity control. Class V wells make up the bulk of UIC wells at up to 650,000 and well over 70% of UIC wells.

EPA explains:

“Most Class V wells are "low-tech" and depend

on gravity to drain fluids directly below the land surface. Dry wells,

cesspools, and septic system leach fields are examples of simple Class V wells.

Because their construction often provides little or no pretreatment and these

fluids are injected directly into or above an underground source of drinking

water, proper management is important.”

“More sophisticated Class V wells may rely on gravity or

use pressure systems for fluid injection. Some sophisticated systems include

advanced wastewater disposal systems used by industry, experimental wells used

to test new or unproven technologies, and systems used to inject and store

water for later reuse.”

A 1999 EPA study involving 23 Class V well types estimated

that there are more than 650,000 of these wells in use in the U.S. This study looked

at 22 different kinds of Class V injection wells in terms of fluids injected

and developed recommendations for regulation. Some of the well types are agricultural

drainage wells, stormwater drainage wells, car washes, large capacity septic

systems, food processing disposal wells, sewage treatment effluent wells, mine

backfill wells, aquifer remediation wells, some geothermal wells, saline intrusion

barrier wells, aquifer recharge/recovery wells, and subsidence control wells.

Class VI - Wells used for Geologic Sequestration of

Carbon Dioxide

Class VI UIC

wells inject CO2 underground for sequestration. This is an emerging type of injection

well that will become more common as CCUS projects proceed according to

development plans. CO2 is injected as a supercritical fluid under pressure.

These wells must account for CO2 properties such as buoyancy, subsurface mobility,

corrosivity in the presence of water, and large injection volumes. CO2 is more

likely to leak due to its buoyancy. CO2 injection wells also require monitoring,

including comparison of pre-injection and post-injection reflection seismic surveys.

Requirements include site investigation, geologic

modeling, reservoir characterization, and other planning requirements

consistent with other injection well classes. The EPA established rules for

Class VI wells in December 2010. In August 2023 the EPA established environmental

justice provisions for Class VI wells. These call for site selection and continual

public engagement through time that considers potentially affected EJ communities.

Outreach in developing emergency response plans is another requirement. The

phases of a Class VI well are shown below.

The first phase is the pre-permitting phase where

the operator applies for the permit and meets with the permitting authority to

discuss the permit. EPA also encourages public engagement and consideration of potential

environmental justice issues. The second phase is the pre-construction phase includes

review of the permit application, public posting of a draft permit, a 30-day

public comment period, with comments considered before the final permit is

issued. The pre-operation phase involves construction and pre-operation

testing, which is reviewed before permission is given to operate the well. Any

new information from the drilling of the well is incorporated and plans and/or

permits altered as needed. Authorization to inject is then given. The injection

phase is the operating phase of the well. Required ongoing monitoring and

testing results are reported to the permitting authority and through them to

the public. The Area of Review is also re-evaluated. The post-injection phase

involves plugging the well, and monitoring the CO2 plume and pressure front, and the

site is closed pending no identified risks.

The Class VI

well-permitting process includes a completeness review where the regulator makes

sure there are no deficiencies. If there is, a notice of deficiency (NOD) is

returned to the operator to rectify. Without an NOD a completeness review takes

about 30 days. The technical review is next. It involves dialogue between

operators and regulators so that the details of the project are understood, and

environmental protection is assured. This is when a request for additional

information (RAI) may be formally requested. A draft permit is then issued for

public comment. There may be certain conditions relative to the well added to

the permit. Then the final permit is issued. EPA hopes to be able to issue

Class VI permits within 24 months of the application but that is without any

delays due to incompleteness or lacking information. I think this could be

speeded up to a year when more of these permits are reviewed and issued. The

current timeframe is too slow.

EPA has a

Class VI permit tracker. It gives permit progress information. The screenshot

below includes the latest permit stats. The vast majority of wells are in the technical

review process. Only 4 well applications are in the Prepare Final Permit

Decision phase.

References:

Protecting

Underground Sources of Drinking Water from Underground Injection (UIC). U.S. EPA.

Protecting Underground Sources of Drinking

Water from Underground Injection (UIC) | US EPA

Underground

Injection Control Program (Factsheet). U.S. EPA. UIC

Fact Sheet (epa.gov)

Class

I Underground Injection Control Program: Study of the Risks Associated with

Class I Underground Injection Wells. U.S. EPA. March 2001. Class

I Underground Injection Control Program: Study of the Risks Associated with

Class I Underground Injection Wells, March 2001 (epa.gov)

United

States Environmental Protection Agency Underground Injection Control (UIC)

Program Class II Permit Application Completeness Review Checklist. August 2018.

UIC

Class II Permit Application Checklist (epa.gov)

Class

V Underground Injection Control Study. U.S. EPA. Class

V Underground Injection Control Study | US EPA

Environmental

Justice Guidance for UIC Class VI Permitting and Primacy. U.S. EPA. August 17,

2023. Memo

and Environmental Justice Guidance for UIC Class VI Permitting and Primacy -

August 2023 (epa.gov)

Underground

Injection Control (UIC) Class VI Permit Tracker. UIC

Class VI Wells Permit Tracker Dashboard (epa.gov)

Injection Wells. Ohio Department of Natural Resources. Injection Wells | Ohio Department of Natural Resources (ohiodnr.gov)

No comments:

Post a Comment