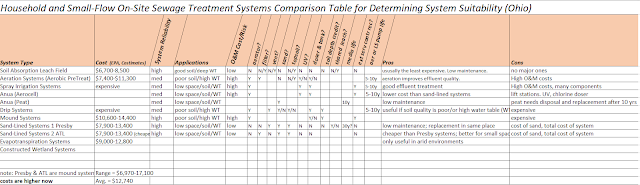

The suitability of

septic system design type is dependent on several factors including soil

quality for leaching, seasonal water table depth, space available for system

size including replacement area, and use parameters. Cost, including ongoing

O&M costs, is always a consideration. Reliability is a concern as well. A low-cost, low-maintenance, high-reliability septic system is obviously the most

desirable choice. However, the abovementioned factors (soil quality, water

table depth, and available space) will determine whether the preferred option

can be installed.

Septic system

sizing includes recommended tank sizes and length of leaching trenches in soil

absorption systems (traditional leach fields, usually with plastic open

chambers). Trench length and number of trenches is based on soil quality and

system size.

System Costs

Septic system

costs vary considerably based on system size, cost of additional components,

and type of system. I recently saw a spray irrigation system for a large 6-bedroom

cabin that cost about $35,000. Average system costs for say a 2 bedroom are

much less than that and the lowest cost, lowest maintenance system is a

soil absorption system that uses leach trenches with chambers. The cost estimates

in my table below are probably low to current prices.

The Regulatory Process of Permitting, Siting,

Sizing, Designing, and Approving Household Sewage Treatment Systems

Here in

Southeastern Ohio the most desirable household sewage treatment system (HSTS)

is a gravity fed system with one septic tank of adequate size for expected use

and appropriately sized leach trenches. These are usually filled with open

chambers consisting of plastic half corrugated half tubes 8-12 inches high and

12 to 24 inches wide. 8” high X 24” wide is a common size. At my house, the

trenches are 34 inches wide. These are open to allow oxygen to get into the

system and assist the filtered effluent to seep into the soil along the trench.

Instead of chambers, trenches filled with perforated pipe and gravel may be

used. These used to be common but open chambers are now the norm where

applicable.

Permits are

given after site visits and soil evaluations to determine site suitability and

soil suitability for different types of systems. The most desirable systems are

those that do not have electrical or other components such as pumps, aerators, chlorinators,

UV lights, and alarms. They also use power and can short out. Operation and maintenance

costs for those systems are much higher. Often, the owner and installer may be

given a menu of design options based on site and soil. After the system type is

approved the system is installed, inspected, and approved.

Systems with components,

especially pumps and aerators, that are often in need of repair or replacement,

may be required to carry extended service contracts with service providers. One-year

inspections are common with systems still under bond or warranty by the

installer to fix any issues. I think 18 months liability is common.

Septic systems

are designed based on available on-contour land with soil of sufficient

permeability and free of restricting layers often indicative of seasonal water

tables. If these conditions are not ideal as is common, then mounded systems,

drip systems, spray systems, and pre-treatment systems are considered.

Gravity-Fed Chamber Leach Line Systems

These very

common systems are most often open-bottom plastic chambers but may also be fabric-wrapped

pipe (such as the EZ Flow design), and synthetic materials such as expanded

polystyrene media. These systems used to be trenches filled with gravel, but

most are now gravelless systems. Microbes on or near the soil treat the sewage

effluent as it flows along and into the soil. Some of these systems may require

a lift station if the available topography does not support gravity-feeding. That

adds the expense of pump maintenance and electricity.

Drip Distribution Systems

These are low-pressure systems with small piping that drips the effluent through the soil. The advantages are that they can be built on shallow soils or soils with a high water table

without mounding. Disadvantages are expense, high O&M costs, and the large

dosing tank that is required in addition to the septic tank.

Aerobic Pretreatment Units

This type of system mimics a municipal sewage treatment system which utilizes aerobic pretreatment. Aerobic pumps called aerators inject oxygen into the effluent water to increase the rate of aerobic decomposition. Disinfection with chlorinators (often passive flow through a chamber with solid chlorinated disks) and UV lights are also used. There are several design types of tanks, aerators, and filters.

Mound Systems

These systems

are used where there is shallow soil depth, high groundwater, or shallow

bedrock. A sand and/or gravel mound is constructed with leaching trenches installed

within. The effluent percolates through the highly permeable sand for a time

before entering the soil below. Common types of mound systems include AES’s

Presby (sand-lined) and ATL Systems. These types often do not require a dosing

tank or a pump tank and so are considered to be low maintenance since passive slow

percolation through the sand and soil absorption are the mechanisms of

treatment. They do require venting, both a low vent from the mound and a high

vent, usually the house vent. Presby systems (but not ATL systems) are eligible

for a 1-foot soil depth credit, which means they can be built closer to the

surface in areas where the water table is high and/or the soil quality is poor.

They are also mounded up, with the sand mound being lightly covered with topsoil.

They have a low failure rate. They can be replaced onsite by removing and

disposing of the sand and adding clean sand. This is expensive but does not

require more space.

Recirculating Sand Filter System

This is similar

to the sand-lined systems but also utilizes low-pressure pumping. Effluent is

recirculated back into a pump tank ahead of the sand filter. After the sand goes through the sand-lined

chamber (the sand filter) it goes on to a soil absorption leach field. Presby

systems, on the other hand, utilize special-made chambers with geotextile fabric

and other design features to enhance treatment within the sand body. I don’t think

I have ever seen one of this type.

Constructed Wetland Systems

According to

EPA:

“The wetland cell typically consists of an impermeable

liner, and gravel and sand fill, along with the appropriate wetland plants,

which must be able to survive in a perpetually saturated environment.”

“A wetland system can work via either gravity flow or

pressure distribution. As wastewater flows through the wetland, it may exit the

wetland and flow into a drainfield for further wastewater treatment into the

soil.”

Wastewater Treatment Lagoons

I have seen sewage treatment lagoons. They are not too uncommon in rural areas and communities with shared treatment. EPA has specific requirements for them. Below is a 'sewage pond' in West Virginia.

Spray Systems

Spray systems

are a newer design that pretreats the effluent with aeration, chlorination, and

UV lights then runs the effluent to sprayers that spray the treated effluent onto

the open ground for final treatment on a timing schedule, The sprayers are

usually programmed to spray at night when no humans are around. These systems

are considered a “green” alternative, but they can be very expensive.

References:

Ohio

Sewage Program Updates. Victoria Miller. Ohio Dept. of Health. Presented at

2024 Contractors Workshop, Logan Ohio. Feb. 15, 2024.

Anua

Systems Operation & Maintenance. Sean McGuigan. Anua. Presented at 2024

Contractors Workshop, Logan Ohio. Feb. 15, 2024.

Alternative

System Applications: Spray, Drip, Mounds, Anua, and Sand-Lined Systems. Katie

Wasky & Jennifer Valentine. Fairfield County Health Dept. Ohio. Presented

at 2024 Contractors Workshop, Logan Ohio. Feb. 15, 2024.

Presby

vs. ATL: An Installers Perspective. Tyler Duncan. Duncan & Daniels

Enterprises. Presented at 2024 Contractors Workshop, Logan Ohio. Feb. 15, 2024.

Pumping

and Maintenance of Transient Rental Systems. Keary Helber. K.G. Helber

Construction. Presented at 2024 Contractors Workshop, Logan Ohio. Feb. 15,

2024.

How

Much Does It Cost to Replace a Septic Tank and Leach Field?: Common Range:

$6,790 – $17,100. National Average: $12,840. Updated: November 17, 2023.

Written by: Steve Hansen. Costimates. November 17, 2023. Septic Tank and Leach Field

Installation Cost | Costimates

Types

of Septic Systems. U.S. EPA. Types of Septic Systems | US EPA

How

Septic Systems Work. U.S. EPA. How Septic Systems Work | US EPA

Small

and Rural Wastewater Systems. Lagoon Wastewater Treatment Systems. U.S. EPA. Lagoon

Wastewater Treatment Systems | US EPA

No comments:

Post a Comment