In previous posts about hydrocarbon gas ratio analysis and drill cuttings volatiles, I talked about

measuring natural gas directly from wells being drilled or from drill cuttings.

These are upstream examples of natural gas measurement. Typical mud logging

units often use flame ionization detection to detect and quantify total gas and

a hydrocarbon gas chromatograph to quantify the main gaseous components,

usually C1-C5. Sometimes, though quite rarely, chromatographs can be outfitted

to detect and quantify heavier hydrocarbons as well. Drill cuttings volatiles

analysis was pioneered by Mike Smith of Advanced Hydrocarbon Stratigraphy.

Smith invented and patented a cryo-mass spectrometer that formed a vacuum below

atmospheric pressure to release hydrocarbon gases from drill cuttings or cores

in sequence according to temperature and pressure. When I was involved in

getting wells drilled and analyzed, we often sent a gas sample to a lab for

more detailed gas analysis. This was very important in fields that had high

levels of different components. If ethane levels were too high, it made the gas

BTU too high for pipeline specs, and the ethane would have to be removed or

blended with lower BTU gas. We had a field area that was very high in nitrogen

and, as a result, suffered from low BTU values. There was a danger that the low

BTU gas would cause things like a pilot light to go out if demand was high in

winter and blending could not be ensured. We looked at building a nitrogen

treatment plant, but the high costs were prohibitive. I took all of the gas

analysis data from the lab and made contour maps of BTU and nitrogen content.

These worked pretty well to predict gas quality in subsequently drilled wells.

Pipelines have specifications

for gas quality, with gas of adequate purity expected to be delivered to the

point of use. In most gas streams closer to distribution, the “contaminants”

are H2S, H2O, O2, and CO2.

According to Alan Garza at

Endress +Hauser, in an article for Gas Processing and LNG:

“The presence of contaminants in distribution pipelines

can cause corrosion, equipment damage, environmental pollution and even rare

catastrophic events that harm human life. As a result, robust gas quality

processing, monitoring and maintenance are essential to ensure compliance with

regulatory standards, and to safeguard gas processing assets, infrastructure

and people.”

“While methods exist to measure and scrub these

impurities, the intermittent nature of certain gas streams—with fluctuating

compositions and contaminants like glycol, methanol, amines and other sulfurous

compounds—complicates reliable gas analysis. As a result, traditional

measurement methods often struggle to accurately identify complex permutations,

which compromises process control and safety.”

Gas processing plants

typically remove these components and others, as well as the heavier natural

gas liquids that can be transported toward the market as their own stream or in

various combinations.

The following section about

natural gas quality standards is from Wikipedia.

“Raw natural gas must be purified to meet the quality

standards specified by the major pipeline transmission and distribution

companies. Those quality standards vary from pipeline to pipeline and are

usually a function of a pipeline system's design and the markets that it

serves. In general, the standards specify that the natural gas:

“Be within a specific range of heating value (caloric

value). For example, in the United States, it should be about 1035 ± 5% BTU per

cubic foot of gas at 1 atmosphere and 60 °F (41 MJ ± 5% per cubic metre of gas

at 1 atmosphere and 15.6 °C). In the United Kingdom the gross calorific value

must be in the range 37.0 – 44.5 MJ/m3 for entry into the National Transmission

System (NTS).”

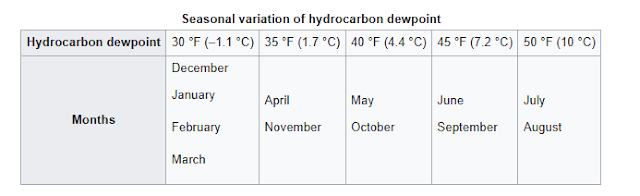

“Be delivered at or above a specified hydrocarbon dew

point temperature (below which some of the hydrocarbons in the gas might

condense at pipeline pressure forming liquid slugs that could damage the

pipeline.) Hydrocarbon dew-point adjustment reduces the concentration of heavy

hydrocarbons so no condensation occurs during the ensuing transport in the

pipelines. In the UK the hydrocarbon dew point is defined as <-2 °C for

entry into the NTS. The hydrocarbon dewpoint changes with the prevailing

ambient temperature, the seasonal variation is:

“The natural gas should:

“Be free of particulate solids and liquid water to

prevent erosion, corrosion or other damage to the pipeline.”

“Be dehydrated of water vapor sufficiently to prevent

the formation of methane hydrates within the gas processing plant or

subsequently within the sales gas transmission pipeline. A typical water

content specification in the U.S. is that gas must contain no more than seven

pounds of water per million standard cubic feet of gas. In the UK this is

defined as <-10 °C @ 85barg for entry into the NTS.”

“Contain no more than trace amounts of components such

as hydrogen sulfide, carbon dioxide, mercaptans, and nitrogen. The most common

specification for hydrogen sulfide content is 0.25 grain H2S per 100 cubic feet

of gas, or approximately 4 ppm. Specifications for CO2 typically limit the

content to no more than two or three percent. In the UK hydrogen sulfide is

specified ≤5 mg/m3 and total sulfur as ≤50 mg/m3, carbon dioxide as ≤2.0%

(molar), and nitrogen as ≤5.0% (molar) for entry into the NTS.”

“Maintain mercury at less than detectable limits

(approximately 0.001 ppb by volume) primarily to avoid damaging equipment in

the gas processing plant or the pipeline transmission system from mercury

amalgamation and embrittlement of aluminum and other metals.”

Below is a typical natural

gas treatment plant configuration to transform raw natural gas into

pipeline-quality natural gas.

Tunable Diode Laser Absorption Spectroscopy Emerges as a

Leading Technology

Garza goes on in his article

to talk about the limitations of traditional gas analysis, especially that of

using lead acetate tape to detect and quantify H2S, noting that it is “unsuitable

for continuous monitoring and precise measurement.” Another very common

method is UV absorption spectrometry utilizing deuterium lamps. It provides

better accuracy than lead acetate tape and can be used for continuous

monitoring, but has some drawbacks, like interference from sulfuric and

aromatic compounds that occur in natural gas. The deuterium light

source degrades over time, causing measurement issues. An alternative is to add

H2S chromatographic columns, but this often adds too much complexity, cost, and

time to analysis.

Another gas analysis method,

tunable diode laser absorption spectroscopy (TDLAS), is emerging as a reliable

technology to follow gas analysis along the value stream. This is important

because, as Garza noted, the processing methods can add new contaminants.

Therefore, one approach is to check gas quality at different points along the

processing stream. TDLAS is used to analyze gas in many industries. Their benefits and several advantages over other gas analysis methods are given below.

TDLAS analyzers are equipped

with automated validation features that verify they are well calibrated. They

generate calibration and performance evaluation and can generate documentation.

Garza notes that custody transfer points are good locations to measure

contaminant levels of H2S, H2O, CO2, and O2, as shown below, and that detailed

knowledge of pre-processing and post-processing gas quality at each point is

very useful for planning and determining effects on equipment.

Garza goes on to explain the

many uses of TDLAS in the petrochemicals processing industry and in ensuring

gas purity in our gas distribution grids.

“Refiners frequently rely on TDLAS measurement during

flare gas, H2 recycle gas in semi-regenerative catalytic reforming, propane and

propylene mixing, fluid catalytic cracking, and other processes to control

contaminant levels and optimize process efficiency. For example, effective H2S

removal is required in olefin production to prevent catalyst poisoning and

ensure product quality in different refinery applications.”

“Seamlessly ensure quality. In the past,

maintaining rigorous natural gas purity in the utility grid was an ongoing

challenge. However, today’s advanced methodologies—like TDLAS paired with

regimented validation procedures—provide highly accurate, repeatable and

reliable measurement of H2S and other contaminants. This, in turn, empowers

plant personnel to verify process effectiveness, safety, quality assurance and

regulatory compliance, while protecting upstream, midstream and downstream

assets from corrosion and other damage.”

“As the energy landscape continues to evolve, embracing

these advanced gas analytic and other innovative technologies is critical to

ensure safe, reliable and efficient processes, while minimizing emissions.”

Looking at Endress+Hauser’s

website, one can see that they have TDLAS gas analyzers targeted for specific

contaminants such as H2S, H2O, CO2, and trace gases. They note the advantages

of TDLAS over Al2O3 sensors and quartz crystal microbalances, which cannot

distinguish between H2O and methanol. TDLAS analyzers have a lower cost of

ownership than lead acetate tape analyzers and gas chromatographs.

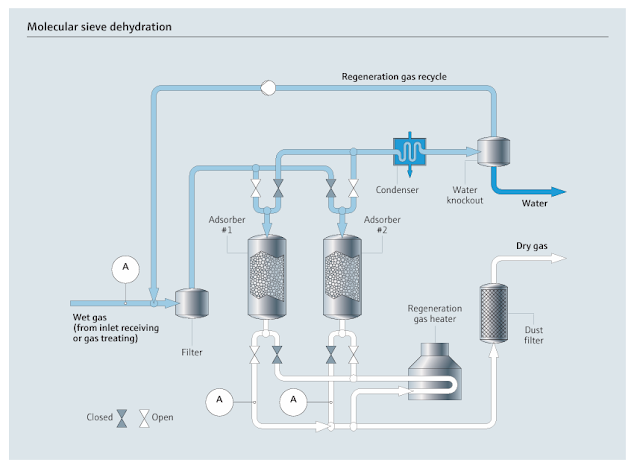

There are three main processing steps for natural gas: 1) amine treatment to remove H2S and CO2 from sour gas, 2) molecular sieve dehydration of the resulting sweet gas, and 3) fractionation to separate and recover NGLs (ethane, propane, butane) from pipeline quality natural gas.

Amine treatment is necessary since about 40% of

natural gas is sour gas containing the so-called acid gases H2S and CO2 in

unacceptable quantities. Many amine treatment plants have a sulfur recovery

unit, which transforms H2S to elemental sulfur.

The post-amine treatment gas

stream is typically saturated with water vapor. Methods such as knockout drums,

compression, and cooling can remove some of the water. However, in order to

fractionate the gas into NGL components or for LNG liquefaction, the water

vapor concentration must be very low (< 0.1 ppm). This is accomplished with

a molecular sieve dehydration unit, shown below.

NGL fractionation recovers

NGLs, typically ethane, propane, butanes, and natural gasoline via cryogenic

fractionation columns. These are utilized for various petrochemical processes

and other end uses. They are abundant in U.S. shale gas, and the U.S. exports

them globally. Below is a fractionation unit configuration. TDLAS gas analysis units can be

used after each of these processes to verify the desired gas quality.

References:

Utilize

tunable diode laser absorption spectroscopy to ensure natural gas purity in the

grid. Alan Garza. Endress+Hauser. Gas Processing & LNG. June 30, 2025. Utilize

tunable diode laser absorption spectroscopy to ensure natural gas purity in the

grid | Gas Processing & LNG

Tunable

diode laser absorption spectroscopy (TDLAS). Endress+Hauser. Tunable

diode laser absorption spectroscopy (TDLAS) | Endress+Hauser

Natural-gas

processing. Wikipedia. Natural-gas

processing - Wikipedia

TDLAS

analyzers for natural gas processing: Accurate and reliable measurement of H2

O, H2S, and CO2. Endress+Haiser. February 2025. TDLAS

analyzers for natural gas processing

No comments:

Post a Comment