Protection from

waterborne diseases from sewage is the main goal of municipal wastewater

treatment. In addition to raw sewage, wastewater treatment plants may receive stormwater

runoff, agricultural runoff, and industrial wastewater that may contain

chemical contaminants. According to the University of Michigan:

“Almost 15,000 POTWs {publicly owned treatment works} treat

and discharge over 34B gal/d of wastewater into U.S. waterways. 1.3M mi of

piping flow toward POTWs provide wastewater collection, treatment, and disposal

service to more than 238M people.”

Along with

protection from waterborne diseases, there is protection from industrial contaminants,

including contaminants of emerging concern (CECs). Mitigating these contaminants

may require new treatment processes.

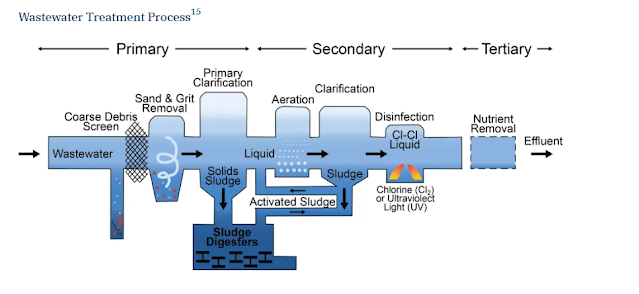

The basic wastewater

treatment process is shown in the graphics below. Primary treatment involves screening,

sand and grit removal (these can damage pumps and equipment), and primary

clarification via sludge digesters. Secondary

treatment includes aeration, clarification via activated sludge, and

disinfection via chlorination and/or ultraviolet (UV) light. Tertiary treatment

includes nutrient removal and discharging the treated effluent back into the environment.

The graphic below shows modern wastewater treatment challenges.

Municipal Wastewater Contaminants and Their Impacts

Microbial

contaminants are the most common contaminants in municipal wastewater. These

include fecal coliform bacteria, viruses, and other pathogens of several types.

These contaminants are classified by the EPA into five types:

·

Oxygen demanding substances: These utilize

the dissolved oxygen in the wastewater and are measured as biochemical oxygen demand

(BOD). Organic contaminants and ammonia have high BODs. These substances use up

the available oxygen supply in the water over time.

·

Pathogens. These infectious microorganisms

can cause waterborne diseases such as typhoid fever, cholera, and dysentery. Those

diseases have largely been eliminated, at least in developed countries like the

U.S.

·

Nutrients. These are basically carbon,

phosphorous, and nitrogen. Secondary treatment only removes a tiny amount of

them so further treatment may be desirable. When discharged into the environment

these can lead to eutrophication and harmful algal blooms and if they get into

local water supplies they can cause undesirable odors and tastes. Therefore, nitrogen

and phosphorous recovery is often employed in tertiary treatment.

·

Inorganic and synthetic organic chemicals. These

can include many different chemicals including household chemicals, pharmaceuticals,

pesticides & herbicides, industrial chemicals, and heavy metals, These can

be harmful and can also cause taste and odor problems if present in local water

supplies.

·

Thermal pollution. Heat reduces the

capacity of water to retain oxygen. Hot weather can be a factor. Water used for

cooling in thermal power plants may be discharged at high temperatures, which

negatively affects some aquatic species, altering the ecology

Screening and Filtration

Primary treatment

involves screening and solids (mainly (grit and sand) removal. The grit and

sand, which mostly come from stormwater sewers, are collected in a sedimentation

tank and periodically removed and trucked away for disposal. The EPA notes some

details about screening strategies and dealing with large floating objects in

sewers by grinding and shredding.

“Screens are generally placed in a chamber or channel and

inclined towards the flow of the wastewater.

The inclined screen allows debris to be caught on the upstream surface

of the screen, and allows access for manual or mechanical cleaning. Some plants use devices known as comminutors

or barminutors which combine the functions of a screen and a grinder. These devices catch and then cut or shred the

heavy solid and floating material. In

the process, the pulverized matter remains in the wastewater flow to be removed

later in a primary settling tank.”

Primary Coagulation and Sedimentation

This process is

often part of primary treatment but is also used in nutrient control in tertiary

treatment. In primary treatment, the process may involve sedimentation or gravity

settling, chemical coagulation, or filtration. This primary sludge is removed

mechanically, either while the plant is running or after shutting down or

bypassing the tank.

Aerobic Treatment: Aeration and Activated Sludge

Secondary

treatment is basically biological treatment followed by disinfection. Aerobic

treatment of sewage-laden wastewater includes aeration in order to increase

oxygen availability and the use of aerobic bacteria in activated sludge to

decompose the waste. According to the EPA:

“Activated Sludge is a suspended growth process for

removing organic matter from sewage by saturating it with air and

microorganisms that can break down the organic matter.”

This process removes up to 90% of the organic matter. Thus,

one might refer to it as carbon removal. There are two main types of aerobic

treatment: attached growth processes and suspended growth processes.

In attached growth processes microbial growth occurs on the surface of stone or

plastic media. The wastewater passes over the media along with air to provide

oxygen. Attached growth process units

include trickling filters, biotowers, and rotating biological contactors. According

to the EPA suspended growth processes biodegrade

“…by converting ammonia nitrogen to nitrate unless

additional treatment is provided. In suspended growth processes, the microbial

growth is suspended in an aerated water mixture where the air is pumped in, or

the water is agitated sufficiently to allow oxygen transfer. Suspended growth

process units include variations of activated sludge, oxidation ditches and sequencing

batch reactors.”

This process speeds up biodegradation. In aeration, air is

added mechanically or pressure pumped into the aeration tank via small openings

as shown below to increase oxygen as the process proceeds.

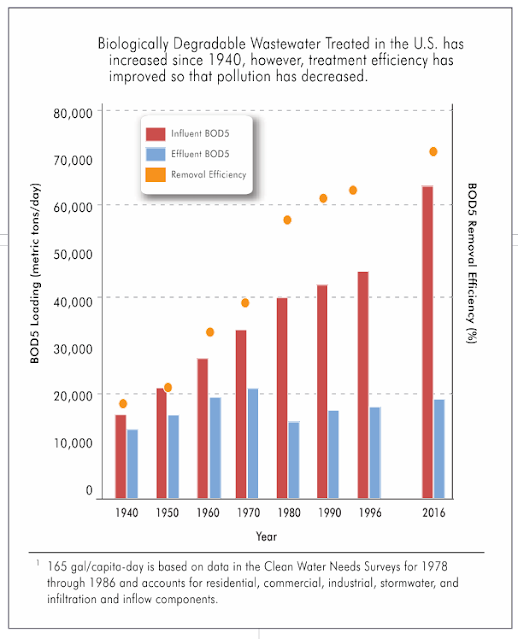

The graph below

shows that over time wastewater treatment in the U.S. has gotten more

effective at reducing BOD, with removal efficiency doubling since 1960.

Sludge Removal

It is estimated

that one-third of the electricity used in a municipal WWTP is used for treating

and removing sludge. Sludge treatment is basically secondary treatment or aerobic

treatment. Aeration and clarification

tanks collect sludge that needs to be removed. In the past the plants had to be

taken offline, or sections bypassed in order to remove sludge but new methods

include removal of sludge during plant operation by robots. Company Sciphyn

offers robotic sludge removal:

“Our robots drive along the floor removing the sludge

which is then dewatered on-site prior to disposal. By avoiding the shutdown or

bypass of your normal operations, our method can result in significant cost

savings.”

Disinfection

Disinfection is a

part of secondary treatment that basically is used to kill pathogens. This step

is essential for protecting people. Chlorine is the most common method of

disinfection, but UV light is also common, and both may be utilized together.

Since any remaining uncombined chlorine after treatment would be dangerous for

aquatic life the wastewater is often dechlorinated before discharging into the

environment. Dechlorination typically involves the use of a reducing chemical

such as sodium bisulfite (NaHSO³) or sulfur dioxide (SO²). Ozone is sometimes

used for disinfection but is not economical. UV light, typically provided by

mercury arc lamps, is an effective means of disinfection but must be provided

at adequate levels to fully neutralize pathogens. UV treatment has the

advantage of not producing toxic byproducts.

Urine Diversion: Opportunities for Nutrient Recovery and

Urine-Derived Fertilizer Production

Urine diversion

is simply diverting and collecting the urine component of municipal wastewater

to be converted into fertilizer and/or mitigated through aerobic (usually) bioreaction.

Urine diversion has been proposed as an approach for producing renewable

fertilizers and reducing nutrient loads to wastewater treatment plants. A 2021

study in Environmental Science and Technology concluded that urine diversion

has great potential for helping WWTPs in several ways. In the study, two

methods were analyzed: a urine concentration alternative and a struvite

precipitation and ion exchange alternative.

“Both urine diversion technologies had better

environmental performance than the conventional system and led to reductions of

29-47% in greenhouse gas emissions, 26-41% in energy consumption, approximately

half the freshwater use, and 25-64% in eutrophication potential, while

acidification potential ranged between a 24% decrease to a 90% increase. In

some situations, wastewater treatment chemical requirements were eliminated.

The environmental performance improvement was usually dependent on offsetting the

production of synthetic fertilizers. This study suggests that urine diversion

could be applied broadly as a strategy for both improving wastewater management

and decarbonization.”

An August 2023

paper in Desalinization noted:

“Source separation of urine can be one of the most

effective solutions for nutrient recovery as a fertiliser, transforming the

conventional linear economy into a circular economy. The urine diversion from

wastewater can improve conventional wastewater treatment plants to be

energy-efficient and cost-effective, as a considerable quantity of nutrients in

wastewater is derived from urine.”

In August 2022

Australian researchers published a paper in analyzing the impacts of urine

diversion on treatment capacity, process design, and capex of a WWTP. The

highlights from that paper and a graphic that shows the nitrogen and phosphorus

that can be diverted are shown below.

These papers show

that urine diversion can be effective for increasing treatment capacity and

reducing capex for WWTPs. If I am reading this correctly, this is important because

it can help prevent the need to expand WWTP treatment capacity, where

applicable.

Nitrogen, Ammonia, and Phosphorus Control

As noted,

secondary treatment does not remove nitrogen and phosphorous. Thus, advanced or

tertiary treatment for nutrient removal requires physical and chemical methods including

adsorption, flocculation/precipitation, membranes for advanced filtration, ion

exchange, and reverse osmosis.

“…nitrifying bacteria present in wastewater treatment can

biologically convert ammonia to the non-toxic nitrate through a process known

as nitrification. The nitrification process

is normally sufficient to remove the toxicity associated with ammonia in the

effluent. Since nitrate is also a

nutrient, excess amounts can contribute to the uncontrolled growth of algae. In situations where nitrogen must be

completely removed from effluent, an additional biological process can be added

to the system to convert the nitrate to nitrogen gas.”

The conversion to nitrogen gas is accomplished by bacteria

in a process known as denitrification.

Phosphorous removal

involves a coagulation-sedimentation process along with chemical additives. A process

known as biological nutrient removal (BNR) can remove both nitrogen and

phosphorous. The EPA explains the process of chemical coagulation-sedimentation

for phosphorous removal:

“A process known as chemical coagulation-sedimentation is

used to increase the removal of solids from effluent after primary and

secondary treatment. Solids heavier than water settle out of wastewater by gravity.

With the addition of specific chemicals, solids can become heavier than water and

will settle.”

“Alum, lime, or iron salts are chemicals

added to the wastewater to remove phosphorus. With these chemicals, the smaller

particles ‘floc’ or clump together into large masses. The larger masses of particles

will settle faster when the effluent reaches the next step--the sedimentation tank. This process can reduce the concentration of phosphate

by more than 95 percent.”

The recovery of

ammonia from wastewater via biochemical processes is an emerging technology.

Since ammonia is a desirable chemical and can even be used as an energy source,

this may be practiced more in the future. Ammonia recovery is a form of nitrogen

recovery. According to MDPI and a 2022 paper in Environments, the following are

methods of ammonia and nitrogen removal from wastewater.

·

Bioelectrochemical system (BES)

·

Membrane electrosorption (MES)

·

Electrochemical stripping (ECS)

·

Electrodialysis (ED)

Other technologies for recovering nitrogen from

wastewater include air stripping, zeolite adsorption through ion exchange,

struvite precipitation, electrodialysis and reverse osmosis, and gas-permeable

membrane (GPM) technology.

New research from Sweden indicates that

phosphorous-rich sewage sludge can be converted into biochar. Biochar is made

via pyrolysis or burning in an oxygen-free chamber. The researchers combined

the sludge with agricultural residue at different amounts and temperatures. The

result is a phosphorous-rich carbon source that can improve soil fertility and

add phosphorous along with the known soil-building qualities of biochar. The

agricultural residue-biochar mix can also reduce the amount of heavy metals in the final

product. The lead researcher noted:

"By testing different compositions of materials and

different temperatures, I have been able to investigate the properties of

biochar to see how it can be improved to remove heavy metals, recover

phosphorus and ensure the long-term stability of biochar for applications in

the agricultural and environmental fields," explained Vali.

Odor and Corrosion Control

Odor control is an obvious need at WWTPs and

most of the odor derives from sulfides, primarily hydrogen sulfide (H2S). This

highly poisonous gas stinks. Odor control, or sulfide control is typically achieved

chemically with iron salts, calcium nitrate, and hydrogen peroxide (H2O2). H2S

is also highly corrosive so odor control is also corrosion control. The basic

oxidation reaction for H2S via H2O2 is:

H2O2 + H2S → S0 + 2H2O

Challenges to using H2O2 for odor control include providing adequate

reaction times. The process needs to be tweaked often.

Management of Contaminants of Emerging Concern (CECs)

According to the

2022 volume Wastewater Treatment:

“Emerging contaminants (ECs), termed contaminants of

emerging concern, emerging pollutants (EPs), micro-pollutants, or trace organic

compounds (TrOCs) are derived from different natural as well as anthropogenic

sources that extensively influence water quality. They are termed as emerging

not because they are new but due to enhancement in the level of concern. These

contaminants are generally in small concentrations, ranging from nano-gram per

liter (ng L−1) to micrograms per liter (μg L−1) in the atmosphere. United

States Environmental Protection Agency (USEPA) describes ECs as new chemical

compounds that have the potential to cause harmful effects on individual health

and the surroundings. It is essential to treat and recycle wastewater to an

acceptable standard to fulfill water demands.”

These compounds may include many different chemicals and

sources as shown below.

Some of the treatment methods along with their benefits and

challenges are shown in the table below.

A 2021 paper in

Science of the Total Environment concluded that ozonation and activated carbon

are the best-performing tertiary treatments available for treating emerging contaminants.

Biosolids Management: Anaerobic Treatment for Methane

Recovery and Fertilizer

According to the

EPA:

“Biosolids are processed wastewater solids (“sewage

sludge”) that meet rigorous standards allowing safe reuse for beneficial

purposes. Currently, more than half of

the biosolids produced by municipal wastewater treatment systems is applied to

land as a soil conditioner or fertilizer and the remaining solids are incinerated

or landfilled. Ocean dumping of these solids

is no longer allowed.”

Biosolids are dewatered and then stabilized by composting, heat

treatments, drying, or the addition of lime or other alkaline materials. Land

application of biosolids is currently being criticized and reevaluated due to

the presence of concentrated emerging contaminants such as microplastics and PFAS/PFOS.

Biosolids are

basically a peat-like product that can add carbon, nutrients, and desirable structure

to soils.

In addition to land

application and incineration, biosolids may be added to anaerobic digestors (ADs) to produce both usable methane and fertilizer. These ADs may occur at WWTPs with

the methane being used to power plant processes. The basic method is the two-stage

acid/gas phase system.

Industrial Wastewater Treatment

Industrial

wastewater has quite variable composition depending on the type of industry

producing it. The petrochemicals industry produces different wastewater than the

food & beverage industry, the metals processing industry, the solar

panel industry, or the pharmaceutical industry, for example. According to the

2023 book Anthropogenic Environmental Hazards:

“Contaminants can be grouped into different classes such

as endocrine disrupting compounds (EDCs), pharmaceuticals, pesticides, heavy

metals and metalloids, per- and polyfluoroalkyl substances (PFAS), and

microplastics. Each contaminant upon exposure possesses a specific health

impact on humans and animals as well as on marine life when mixed in the sewer.”

UK company Anguil

notes that wastewater can be challenging to treat due to high pollutant volume,

complex composition, and unpredictable variability. They also note that

automated treatment has driven innovation in recent years. Changes in

industrial operations due to new chemicals, increasing production volumes, or

changing processes are the most common reasons industrial effluent treatment

facilities fail compliance. Other factors include lack of maintenance, adapting

to regulatory changes, aging equipment, and upgrading issues. They note that

some companies opt to pay fines and fees for non-compliance rather than maintaining

equipment. Sometimes companies are not prepared to adapt to regulatory changes

such as updated contaminant limits. Aging equipment may become less effective

at removing contaminants. Upgrading equipment is costly and may be delayed,

triggering non-compliance.

Industrial

effluents vary in difficulty of treatment and each type and instance of wastewater

has its own challenges. They note that common industrial wastewater

contaminants include: total suspended solids (TSS), total dissolved solids

(TDS), dissolved metals, fats, oil, grease (FOG), biochemical oxygen demand

(BOD), chemical oxygen demand (COD), color, inorganic/organic compounds, pH, volatile

organic compounds (VOCs), and solids handling. They recommend water reuse where

applicable, for example, treating water to certain standards to be able to run

similar or other operations, such as boiler feedwater. This is a good way to

reduce total effluent discharge volumes. Anguil fits solutions to problems by

leveraging all existing wastewater treatment methods to find the best option for

each application according to client capabilities. They note:

“The industrial wastewater treatment solutions we offer

are developed from a collaborative process with our customer to understand

their needs, then validated through lab or pilot testing.”

The U.S. consumes

about 322 billion gallons per day. About half of this consumption is in industrial

applications. Anguil notes that industrial effluent contaminant management is

costly, whether that is through fines, which don’t address the issue, or through

added remediation and associated transportation costs, which do address the issue.

Typically industrial wastewater must be pretreated before it can be further

treated at municipal wastewater treatment plants. They also note that the

relationship between municipal and wastewater treatment plants and industrial wastewater

producers can change:

“Municipalities find it more cost-effective to tighten

standards for industrial clients rather than expand their own facilities. This

approach helps reduce the burden on the municipal treatment system. Industrial

companies then face the challenge of finding economical ways to meet these new

criteria to avoid penalties and surcharges.”

They also note that

in-house or on-site treatment options can save money on transportation costs. They

note that costs are important:

“The primary focus of most wastewater treatment solutions

is to discharge wastewater in compliance with national and local regulations.

The secondary goal is to be as cost-effective as possible when treating

wastewater.”

Treating

industrial wastewater involves contaminant-specific technologies. Anguil lists

the major ones below:

- Heavy

metals/dissolved metal materials can be removed through pH

adjustment and clarification, ion exchange, and carbon technologies.

- Dissolved

Air Flotation (DAF) and oil-water separators remove fats, oils, and

grease from wastewater.

- Filter

presses, belt presses, rotary vacuum drums, and rotary screw presses

squeeze water from sludge to achieve dewatering.

- Cartridge

filters, ballasting, parallel plate clarifiers, DAF, and bag filters

remove suspended solids.

- MBBR,

MBR, anaerobic, anoxic, bioreactor, and oxidation treatment eliminates

soluble biochemical oxygen demand (BOD) and chemical

oxygen demand (COD).

- Total

dissolved solids (TDS) are the measurement of the total

dissolved amount of organic and inorganic solid materials present in

wastewater. Reverse osmosis, ion exchange systems, and nanofiltration

facilitate the removal of TDS.

- Volatile

organic compounds (VOCs) are often present in wastewater,

requiring removal via air stripping, granular activated carbon (GAC)

adsorption, or oxidation.

- Ultra-pure

water requires the removal of minerals and other

contaminants from relatively clean water. Reverse osmosis (RO),

deionization (DI), ion exchange, ultrafiltration (UF), and microfiltration

are a few technologies that can be leveraged to create ultra-pure process

waters.

Their process

evolves from assessment to lab testing to pilot project and finally to final

project design and construction as shown below.

The table below

shows industrial wastewater treatment technologies and equipment in more

detail.

Industrial Wastewater Evaporation

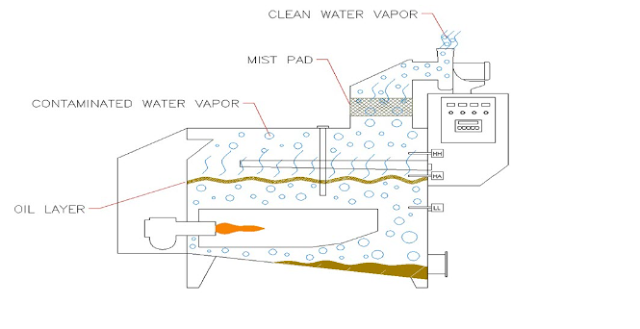

Another way to

reduce industrial effluent volumes is through evaporation. Company ENCON Evaporators

offers several high-tech evaporators. Several types are shown below. Their

applications vary according to the composition and amount of wastewater. The

goal is to minimize the amount of wastewater to be treated. They explain

wastewater evaporation below:

“In its simplest form, the evaporator converts the water

portion of water-based wastes to water vapor, while leaving the higher boiling

contaminants behind. These wastewater evaporation solutions greatly minimize

the amount of waste that needs to be hauled off-site.”

“The evaporation process itself involves both a

thermodynamic and mass transfer phenomena.”

“The thermodynamic phenomenon of evaporation nvolves

providing enough heat energy (waste oil, off-spec gas, natural gas, propane,

oil, diesel, electricity, or steam) to convert water to water vapor.’

“The mass transfer phenomenon of evaporation can best be

described as the “carry off” of small droplets of water. These droplets are

created at the surface of vigorously boiling water and are “carried off” by

oversized blowers or unfiltered water vapor.”

“This “carry off” is problematic with wastewater

applications since the droplets of water may have contaminants such as soaps,

metals, or oils entrained in them, thus causing an environmental impact outside

the building.’

“This “carry off” of droplets is minimized on all ENCON

wastewater evaporators through use of a mist eliminator and other design

considerations.”

They note that if

the waste stream is over 70% water, then it is likely a good candidate for

evaporation. To determine if it is suitable requires some preliminary chemical laboratory

analysis.

References:

Challenges

with Industrial Wastewater Compliance. Anguil. Challenges with Industrial Wastewater

Compliance | Anguil Environmental Systems, Inc.

Understanding

Wastewater Treatment Challenges & Solutions. Anguil. Understanding

Wastewater Treatment Challenges & Solutions | Anguil Environmental Systems,

Inc.

Industrial

Wastewater Treatment Solutions. Anguil. Industrial Wastewater Treatment

Solutions

U.S.

Wastewater Treatment Factsheet. University of Michigan, Center for Sustainable

Systems. U.S. Wastewater Treatment Factsheet |

Center for Sustainable Systems

Life

Cycle Assessment of Urine Diversion and Conversion to Fertilizer Products at

the City Scale. Stephen P Hilton, Gregory A Keoleian, Glen T Daigger, Bowen

Zhou, Nancy G Love. Environmental Science & Technology. 2021 Jan

5;55(1):593-603. Life Cycle Assessment of Urine Diversion and

Conversion to Fertilizer Products at the City Scale - PubMed

Nutrients

in a circular economy: Role of urine separation and treatment. Weonjung Sohn,

Jiaxi Jiang, Sherub Phuntsho, Yeshi Choden, Van Huy Tran, and Ho Kyong Shon. Desalination.

Volume 560, 15 August 2023, 116663. Nutrients in a circular economy: Role

of urine separation and treatment - ScienceDirect

Impact

of source-separation of urine on treatment capacity, process design, and

capital expenditure of a decentralised wastewater treatment plant. Umakant

Badeti, Jiaxi Jiang, Abdulaziz Almuntashiri, Nirenkumar Pathak, Ugyen Dorji,

Federico Volpin, Stefano Freguia, Wei Lun Ang, Amit Chanan, Sanjay

Kumarasingham, Ho Kyong Shon, and Sherub Phuntsho. Chemosphere. Volume 300,

August 2022, 134489. Impact of source-separation of urine

on treatment capacity, process design, and capital expenditure of a

decentralised wastewater treatment plant - ScienceDirect

Treatment

technologies for emerging contaminants in wastewater treatment plants: A review.

Prangya R. Rout, Tian C. Zhang, Puspendu Bhunia, Rao Y. Surampalli. Science of

The Total Environment. Volume 753, 20 January 2021, 141990. Treatment technologies for emerging

contaminants in wastewater treatment plants: A review - ScienceDirect

Wastewater

Contaminants Research. U.S. EPA. Wastewater Contaminants Research | US

EPA

ENCON

Wastewater Evaporation Products. ENCON Evaporators. Wastewater Evaporation Equipment -

Self Contained Wastewater Treatment System | ENCON Evaporators

What

is Wastewater Evaporation? ENCON Evaporators. Industrial Wastewater Evaporation -

Wastewater Solutions | ENCON Evaporators

How

Does Evaporation Compare to other Wastewater Disposal Methods? ENCON

Evaporators. Wastewater Disposal | ENCON

Evaporators

Wastewater

Treatment: Robotic Waste Water Sludge Removal. Sciphyn. Waste Water Sludge Removal | Sciphyn

Technologies

for Removal of Emerging Contaminants from Wastewater. Tahira Mahmood, Saima Momin,

Rahmat Ali, Abdul Naeem and Afsar Khan. Published: 12 May 2022. Wastewater

Treatment. Edited by Muharrem Ince and Olcay Kaplan Ince. Technologies for Removal of Emerging Contaminants from

Wastewater | IntechOpen

Hazards

Associated with Industrial Effluents and Its Mitigation Strategies. Chapter in

Anthropogenic Environmental Hazards. Compensation and Mitigation. Ziaul Haque

Ansari & Uttam Bista. 28 October 2023. pp 89–117. Hazards Associated with Industrial

Effluents and Its Mitigation Strategies | SpringerLink

Primer

for Municipal Wastewater Treatment Systems. U.S. EPA. EPA 832-R-04-001. September

2004. Primer for Municipal Wastewater

Treatment Systems

What

Is Municipal Wastewater Treatment – Essential Guide. Etch2o. July 2, 2023. What Is Municipal Wastewater

Treatment - Essential Guide 2025 | Etch2o

Biochar

key to new method for recovery of vital phosphorus from sewage sludge. Science

X staff. Phys.org. February 3, 2025. Biochar key to new method for

recovery of vital phosphorus from sewage sludge

Wastewater

Odor Control. USP Technologies. Wastewater Odor Control - USP

Technologies

"Transforming

Wastewater: The Future of Ammonia Recovery as an Eco-Friendly Energy

Source". Posted on LinkedIn by Ahmed Elgarahy, Ph.D. (23) Post | Feed | LinkedIn

PFAS:

ramping up clean-up campaigns. Desotec. PFAS: ramping up clean-up campaigns |

Desotec

Converting

from Chlorine Treatment to Alternate Types of Municipal Wastewater Treatment. Trojan

Technologies. Converting from Chlorine to UV

Treatment | Trojan Technologies

Effect

of Operational Conditions on Ammonia Recovery from Simulated Livestock

Wastewater Using Gas-Permeable Membrane Technology, Berta Riaño, Beatriz

Molinuevo-Salces, Matías B. Vanotti, and María Cruz García-González. Environments

2022, 9(6), 70; https://doi.org/10.3390/environments9060070.

Biosolids

Technology Fact Sheet: Multi-Stage Anaerobic Digestion. U.S. EPA. August 2019. Biosolids

Technology Fact Sheet, Multi-Stage Anaerobic Digestion