The utilization

of captured carbon is an important component of decarbonization. Currently, the

vast majority of utilized captured CO2 is used for enhanced oil recovery. That

is about to change according to forecasts. Due to tech advancements and generous

incentives from the Bipartisan Infrastructure Bill and the IRA the U.S. is on

the verge of increasing the utilization of captured CO2. The DOE’s Office of

Fossil Energy and Carbon Management developed a grant program in 2022, their Carbon

Utilization Program, that “is designed to establish a grant program for

state and local governments to procure and use products derived from captured

carbon oxides.” Initial funding was $310 million.

The graph below

shows the different carbon utilization possibilities. Aquaculture can utilize

carbon in biomass to yield algae through dewatering, to yield biochar, biogas/syngas,

or biocrude through conversion, or to yield lipids, proteins, or carbohydrates

through fractionation. Through carbonization, carbon can be converted to

inorganic materials which can yield biocarbonates, carbonate aggregates, carbon

cements, and other inorganic materials and chemicals. Carbon can be converted

into fuels and organic chemicals via two methods: biotic synthesis and abiotic

synthesis. Biotic synthesis can yield neat fuels and blendstocks, commodity,

specialty, and fine chemicals, and emerging biochemicals. Abiotic synthesis can

yield comm oddity, specialty, and fine chemicals through carbon insertion. Through

carbon coupling abiotic synthesis can yield C2 basic chemicals, graphite, and

carbon. Through C1 reforming abiotic synthesis can yield CO, syngas, and C1

basic chemicals. Captured carbon can also be used as a working fluid to provide

services, mainly for improved resource recovery. Crude oil, natural gas, coalbed

methane, groundwater, wastewater, and geothermal energy can all utilize CO2 as

a working fluid to improve recoveries.

IDTechEx forecasts

that the percentage of captured carbon used for enhanced oil recovery will drop

from the current 90+% to about 50% by 2044. That does not mean that enhanced

oil recovery won’t increase, just that it will be less of the total share of captured

carbon utilized. They also forecast that CO2 conversion to fuels and to

building materials, in roughly equal measure will dominate the new uses for captured

carbon as the graph below shows. Conversion to chemicals and biological

products will make up a much smaller share.

IDTechEx predicts that by 2044,

utilization of waste CO2 will reach 800 Mt, creating over 3,000 Mt of useful

products. Of course, CO2 converted to fuels and some chemicals and other

products will be burned or consumed, re-releasing the captured CO2 to the

atmosphere, but without any new CO2 being generated. Other products like CO2-imbued

building materials and biochar will be sequestered for a long time. CO2

sequestration into deep saline reservoirs offers the longest-term storage. Government

requirements, mandates, new regulatory rules, and incentives are expected to

help fuels and building materials to utilize more captured CO2. They also note

that CO2 utilization for crop enhancement in greenhouses is expected to grow as

new CO2 pipelines are constructed and filled. The graph below shows emerging applications

for the utilization of captured CO2. They also note that some chemicals such as CO2-derived

polycarbonates are already produced commercially but they do not require very

much CO2 to make, and that chemicals that require non-reductive pathways are

the most promising due to a smaller energy demand.

A paper published

in November 2019 in Nature addressed the technological and economic prospects

of CO2 utilization and removal. The authors also pointed out some co-benefits

od certain utilization pathways. One example is land-based CO2 sequestration

into products like biochar can increase agricultural yields and soil health. Another

example is that the use of carbon in construction materials can reduce the

amounts of other materials required as well as offering a fairly permanent

storage solution. The paper provides ten potential utilization pathways that can

be scaled up to utilize over 0.5 gigatons of CO2 annually each. The ten

pathways are shown in the graphic below of stocks and net flows of CO2 in the

environment and in the table below:

CO2 flows from the different types of utilization and

removal are shown below.

The last two graphs from the paper address economics and breakeven costs for

2019. Since then, some costs likely have risen due to inflation and higher

borrowing costs but that is likely to have been more than offset by new

subsidies and incentives as well as some technological improvements. The

authors mention a few possible tech improvements that could decrease costs: “The

emissions-reduction potentials of the three cycling pathways would be

facilitated by declines in the costs of CO2 capture. New sorbents could reduce

the cost of energy-intensive separation of CO2 from flue gases and industrial

streams.” They emphasize that new materials and catalysts can be employed

to decrease the costs of CO2 utilization.

A summary for

a CO2 utilization market report by Research and Markets describes the scope of

the report: “Multiple product opportunity areas are examined including

synthetic hydrocarbon fuels and feedstocks, polycarbonates, polyols, industrial

gases, enhanced oil recovery, yield boosting technologies, carbon nanomaterials, and sustainable building products.” The report also addresses regional outlooks

for carbon utilization, market challenges, drivers, and industry players.

I wrote about

carbon utilization in my 2022 book: Natural Gas and Decarbonization.

There I focused on some current projects as well as the DOE-NETL’s utilization

projects, about three-quarters of which were focused on conversion to fuels and

chemicals. Only five, or one-eight of the projects were focused on mineral

carbonization to produce building products like CO2-imbued concrete and other

composite construction materials. I also wrote about the possibility of developing

a carbon nanotube and fibers industry to replace the use of metals, which could

make products lighter and more durable. The idea was developed by Rice

University carbon materials expert Matteo Pasquali. Along with cost, the big

hurdle is developing manufacturing capacity for scale-up that can compete with

metals manufacturing. Replacing metals with carbon nanomaterials can reduce

carbon emissions significantly if such an industry is developed. This is

because sources of carbon such as hydrocarbons in the earth are much more

concentrated than metal ores. While conversion to chemicals won’t utilize as

much carbon as conversion to fuels, there are many chemicals into which CO2 can

be converted. I wrote about Lanza Tech’s biological conversion of algae biomass

into sustainable jet fuel and their conversion of ethanol into polyester.

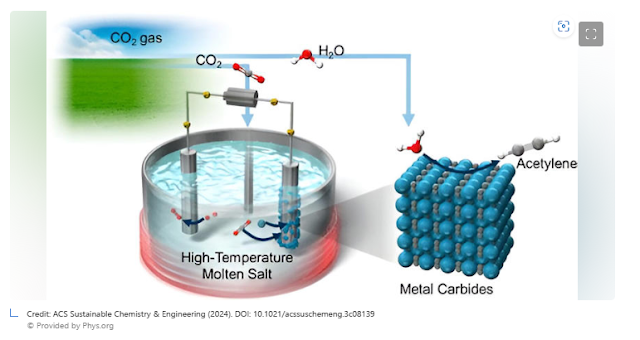

Today,

I read about new research to convert CO2 and water into acetylene gas (C2H2),

which has many uses including in welding, industrial cutting, metal hardening,

heat treatments, and other industrial processes. The idea is to use captured

CO2 and water as feedstock rather than fossil fuels. The process requires the

use of high-temperature molten salts. The images below show some of the

details:

Another major

obstacle to the cost-effective conversion of CO2 into useful products via

electrochemical conversion is the breakdown of catalysts under standard

operating conditions. Researchers at McMaster University recently published a

paper in Nature that used electron microscopy to see within the conversion

process to determine how the catalysts break down and to inform strategies that

could extend the operational lifetimes of these catalysts, particularly palladium-based

catalysts. Just seeing the process at nanoscale is a key development for future

improvement. An understanding of catalyst degradation can lead to increasing

the stability and operational lifetime of the catalysts.

References:

Researchers

reveal elusive bottleneck holding back global effort to convert carbon dioxide

waste into usable products. Science X staff. Phys.org. February 2024. Researchers reveal elusive bottleneck

holding back global effort to convert carbon dioxide waste into usable products

(phys.org)

Impact

of palladium/palladium hydride conversion on electrochemical CO2 reduction via

in-situ transmission electron microscopy and diffraction. Ahmed M. Abdellah,

Fatma Ismail, Oliver W. Siig, Jie Yang, Carmen M. Andrei, Liza-Anastasia

DiCecco, Amirhossein Rakhsha, Kholoud E. Salem, Kathryn Grandfield, Nabil

Bassim, Robert Black, Georg Kastlunger, Leyla Soleymani & Drew Higgins.

Nature Communications volume 15, Article number: 938. January 31, 2024. Impact of palladium/palladium hydride

conversion on electrochemical CO2 reduction via in-situ transmission electron

microscopy and diffraction | Nature Communications

Carbon

Utilization Program. U.S. Dept. of Energy. Office of Fossil Energy and Carbon

Management. Carbon

Utilization Program | Department of Energy

About

Carbon Utilization. U.S. Dept. of Energy. National Energy Technology

Laboratory. About

Carbon Utilization | netl.doe.gov

Utilization

of Captured CO2 to Reach 800 Mt by 2044, Finds IDTechEx. IDTechEx. January 23,

2024. Utilization

of Captured CO2 to Reach 800 Mt by 2044, Finds IDTechEx (prnewswire.com)

Carbon

Dioxide Utilization 2024-2044: Technologies, Market Forecasts, and Players. Eve

Pope. IDTechex. January 2024. Carbon

Dioxide Utilization 2024-2044: Technologies, Market Forecasts, and Players:

IDTechEx

Carbon

Capture, Utilization & Storage Technologies Market Outlook 2024 : Trends,

Challenges and Key Suppliers Analysis By 2031. Fashion Trend Segment. LinkedIn.

March 8, 2024. (21)

Carbon Capture, Utilization & Storage Technologies Market Outlook 2024 :

Trends, Challenges and Key Suppliers Analysis By 2031 | LinkedIn

Report is by 360 Research Reports with link below. https://www.360researchreports.com/enquiry/request-sample/20311849

Carbon

Dioxide (CO2) Utilization Global Market Report 2024-2045: Emerging Concepts

Around Mineralization Pathways for Carbon Removal. PR Newswire. January 25,

2024. Carbon

Dioxide (CO2) Utilization Global Market Report 2024-2045: Emerging Concepts

Around Mineralization Pathways for Carbon Removal (yahoo.com)

Discover

20 Startups advancing Carbon Capture Utilization & Storage (2024). Startus

Insights. 20

Startups advancing Carbon Capture Utilization & Storage (2024)

(startus-insights.com)

The

technological and economic prospects for CO2 utilization and removal. Cameron

Hepburn, Ella Adlen, John Beddington, Emily A. Carter, Sabine Fuss, Niall Mac

Dowell, Jan C. Minx, Pete Smith & Charlotte K. Williams. Nature volume 575,

pages87–97 (2019). The

technological and economic prospects for CO2 utilization and removal | Nature

Natural

Gas and Decarbonization: Key Component and Enabler of the Lower Carbon, Reasonable

Cost Energy Systems of the Future: Strategies for the 2020s and Beyond. Kent C.

Stewart. Amazon Publishing 2022.

Advancing

towards sustainability: Turning carbon dioxide and water into acetylene.

Science X Staff. Phys.org. March 27, 2024. Advancing

towards sustainability: Turning carbon dioxide and water into acetylene

(msn.com)

No comments:

Post a Comment