One

mid-morning after a 12-hour night shift I was woken up by a phone call. The man

on the line was looking for a geologist, someone who knows about building

stones in Northeast Ohio. I asked him if it was the Berea Sandstone. He said he

thought that is what it was. He owned what he called a mine, but really meant a

quarry of the stone and was in some kind of dispute about its boundaries and

depth. He needed to know its thickness. Not being an expert in this area I

referred him to the Ohio Geological Survey in Columbus, knowing that they had some

old reports about the Berea Grit, as the sandstone is called in its building and

grindstone manifestation.

Since some of

my blog posts are related to personal experience, I thought I would research

and write a bit about the Berea Grit and its history and qualities as a

building stone. The sand is indeed thick in Northeast Ohio and Western

Pennsylvania. It outcrops in Northeast Ohio, near Cleveland, where it has been

extensively quarried and milled.

As an oil and

gas geologist from Ohio I am well aware of the Berea Sandstone, having mapped

it in Southern Ohio and studied oil and gas production from it. It was once thought

to be of the Early Mississippian period but now is assigned to Late Devonian. The

sand made several river channels through West Virginia and deltas in Western

West Virginia and Ohio. Many of these produce natural gas and oil. I even

mapped one section I interpreted as an ebb tide delta with a single well of

prolific gas production (by Berea standards). A little further in Ohio there is

an older sandstone just below it, known as the Second Berea, that makes up

offshore marine bars. An equivalent sandstone in Western Pennsylvania is known

as the Murrysville Sandstone. The Berea Sandstone is also present as a lower

permeability rock in Kentucky where it produces oil and there is an equivalent but

likely slightly younger sandstone in Michigan. The sediment source of the sand was

the highlands of Eastern Canada.

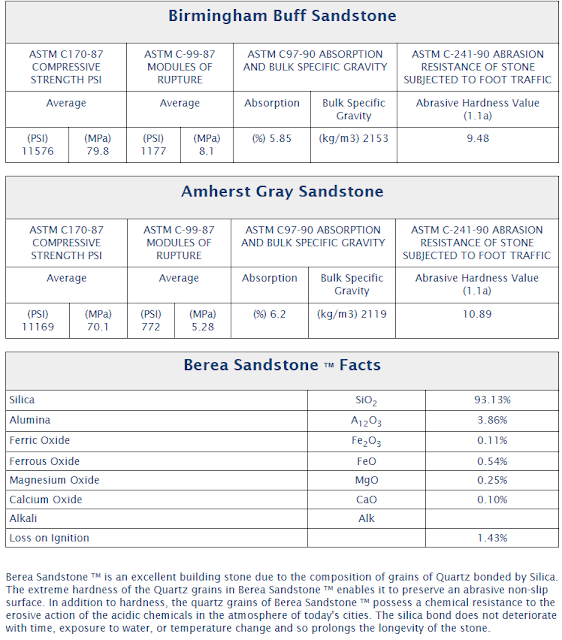

The qualities of

the sand lend themselves well to being a building and grinding stone. Berea Grit

has a high silica content, composed mainly of quartz grains with silica cement.

An old book/magazine from 1896 notes that quarrying of Berea Sandstone began in

1830. First, until around 1840 or 1845, only grindstones were produced. Then flagstones

and building stones were produced. By 1893 the dozen or so companies producing

the stone consolidated into the Cleveland Stone Company, which was the largest

sandstone producer in the United States at the time. As a building stone the

Berea faces several large courthouses and buildings in the U.S. and Canada.

The sandstone

is named after the town of Berea, along the Rocky River, twelve miles southwest

of Cleveland and six miles from Lake Erie. There is an annual Berea Grindstone

festival in the town.

“The requirements for a good, natural grinding stone

are that it be sharp sand, clean—free from clay or other impurities—and

strongly cemented together. However, when this ideal condition is reached, any

further cement is objection-able, since it reduces the grit. The coarser the

stone the faster the cutting. The Berea grit is composed of about 4 percent

super hard aluminum oxide (corundum) bonded with about 93 percent silicon

dioxide (quartz), the remainder being iron, magnesium, and calcium oxide. Near

perfect in grain, the sandstone was ideal, cutting evenly and efficiently.”

The Berea is

also quarried in South Central Ohio as the Waverly Stone but there it is of

lower quality, having a higher clay content. The high-quality Berea Grit in

northern Ohio was easy to cut and milling the stone into shapes resulted in

very little waste. It was used extensively as a grindstone and as a whetstone. In

1915, about 85% of the grindstones in the U.S. were made from Berea Grit.

Unfortunately,

there were some tragedies regarding the stone’s production. Towns with quarries

were jagged and uneven with rock strewn about. The workers, particularly in the

mills where the stone was turned to make grinding wheels, developed silicosis

as the fine silica dust entered and accumulated in their lungs. Many workers

died from it. Incidentally, the more recent increase in black lung disease from

coal mines (after falling somewhat when better safety measures came) is really

attributable to silicosis as mining machines tear through adjacent sandstones to

get to other coal seams. The average time a worker spent in Berea Grit quarries

and mills was just 5 years.

Precision

grinding machines made of alloy steel began to replace grinding stones at the turn

of the century. The steel machines used new synthetic materials for grinding: vitrified

emery, carborundum (silicon carbide), and alundum (artificial corundum) became

the abrasives of choice for grinding wheels. These materials replaced sandstone.

Cheaper concrete and cement replaced the sandstone for use in sidewalks, curbs,

and foundations.

The Berea

Sandstone is also used in the petroleum industry as a standard for testing

cores. “For the past 30 years, Berea Sandstone core samples have been widely

recognized by the petroleum industry as the best stone for testing the

efficiency of chemical surfactants.” A company called Cleveland Quarries supplies

Berea for this purpose as well as for Berea Patio company and other uses. The high

permeability of the sand lends it well for use as a testing standard. Cleveland

Quarries’ Berea Sandstone Cores markets the rock for this use and describes

three grades based on permeability and other features:

“Split Rock has visible laminations but

can be classified as homogeneous. These samples typically yield mD ratings

between 100-300.

Liver Rock has little top no visible

laminations and is homogenous. These samples typically have mD ratings above

500 and can be found with mD ratings up to 900 when measured with air.

Dundee samples are from the Massilon

Formation. While having consistent porosities and densities to our Berea

Sandstone™, our Ohio Sandstone samples are not considered homogeneous. Its

laminations do not run parallel to each other and is very porous, therefore

yielding the higher ratings of 900mD-2500mD.”

References:

Wikipedia: Berea Sandstone. Berea Sandstone - Wikipedia

Rowley, Ira P. (1893). "Sandstone Interests of Northern Ohio - IV". Stone; an Illustrated Magazine. D. H. Ranck Publishing Company. pp. 200–203. Stone; an Illustrated Magazine - Google Books

Ohio’s Sandstone: Once

the source of the World’s Finest Grinding Stones. Dana Martin Batory. Early

American Industries Association. Excerpted from The Chronicle Vol. 60 No. 1,

March 2007. Ohio’s

Sandstone: Once the Source of the World’s Finest Grinding Stones – EAIA

(eaiainfo.org)

Berea Sandstone Patio. Website. Berea Sandstone - Patio stone, sandstone, Cleveland, Ohio (sandstonepatio.com)

Berea Sandstone

Cores. Website. Berea Sandstone

Cores | Cleveland Quarries

No comments:

Post a Comment